Towers represent a major component in most refining and petrochemical processes. In any major plant, you can see one tower or more. An efficient operation of a tower is a bit complicated and depends on many factors.

If you’d like to see the content of this article as a video, you can check out our YouTube video. Otherwise, you can continue reading this article:

What is the job of a tower?

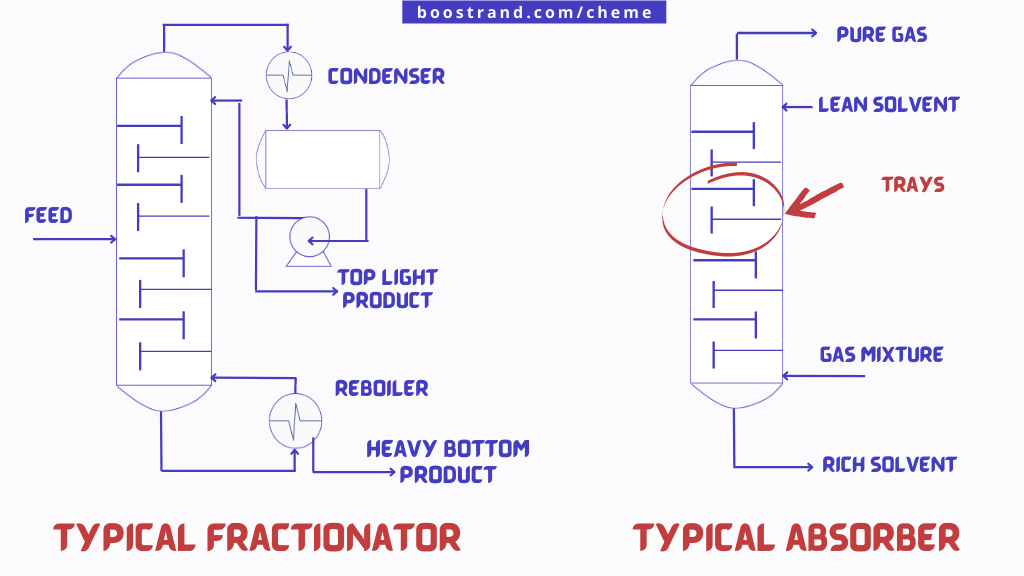

So why would we originally need a tower? Towers represent an efficient separation method where we can separate a mixture into the products we need at their required specifications. They are mainly classified into:

- Absorption Columns: where we can separate a specific component from a mixture of gases using a liquid solvent. An example could be the Amine absorber used to purify the natural gas from H2S.

- Fractionators: where we can separate multiple components from each other depending on the relative volatility of each component. This can be by adjusting the temperature at each tower tray. An example could be the Crude Atmospheric Distillation Columns in refining applications or fractionation trains in gas applications separating Methane, Ethane, Propane, Butane, and Natural Gas Liquids (NGL). These are generally comprising demethanizer, deethanizer, depropanizer, and debutanizer columns.

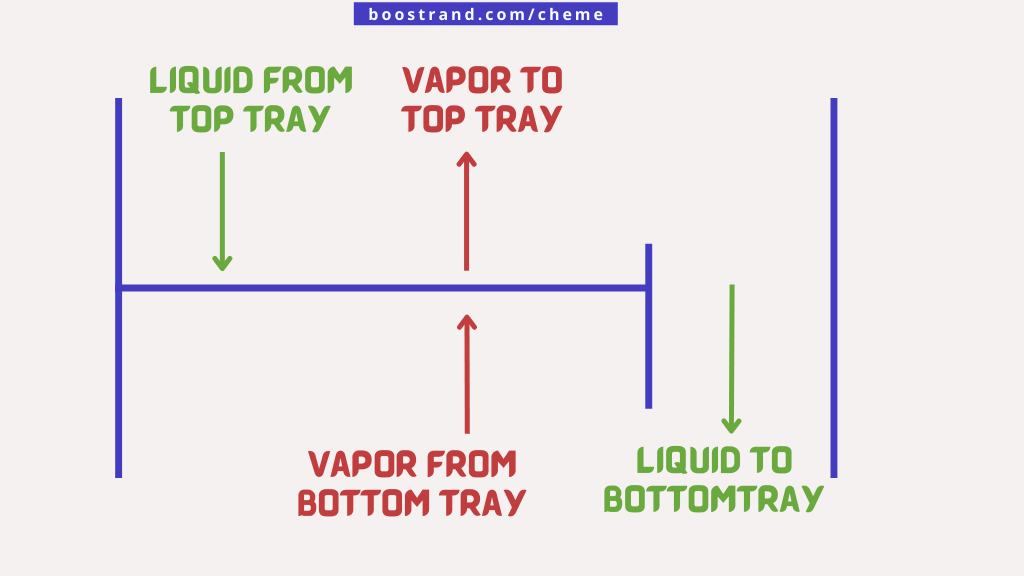

As we can see in the photo, towers consist of various trays. Each tray represents a stage (or a portion of a stage) of separation providing a residence time for mass transfer to occur, i.e. some separation will occur.

Process Data affecting the tower operation

In order to design the tower correctly, we need first to know the major parameters on which the design process shall be based. This includes:

1. Number of Stages

The number of stages would represent the number of trays a tower would need in order to achieve the separation degree we need. Based on material balance calculations and the expected mass transfer that shall happen in each tray and its degree of separation, we can determine the number of theoretical stages. There are basic methods to calculate the number of tower theoretical stages as the McCabe Thiele method for example. However, the number of theoretical stages is usually calculated through rigorous simulation software such as HYSYS or PROII for example.

The number of theoretical stages considers that each tray shall have 100% efficiency, which means that it shall give total separation. However, this is not usually the case. That’s why tray efficiency is assumed for each service. If we know the number of theoretical stages and the tray efficiency, we can determine the number of trays. So if we have 7 theoretical stages, and the tower efficiency is 50%, then the tower shall have 14 trays.

Elevate your Process Engineering skills

Access our courses today!

2. Liquid and Vapor Loads

After we have determined the number of theoretical stages, it’s expected that we now know the flow rates and the physical properties of the liquid and vapor entering the tower. We need to know the details of liquid and vapor in order to make sure we specify the correct tray design. The tray should be able to handle different scenarios without experiencing hydraulic disturbances. As we shall see below, changes in liquid and vapor data may lead to tower instabilities that may cause major issues.

Tower Operation is very sensitive

Tower operation depends on multiple factors. These factors should be all within an acceptable limit in order to ensure that the tower operation is stable and that we have our products with accepted specifications. These factors can be:

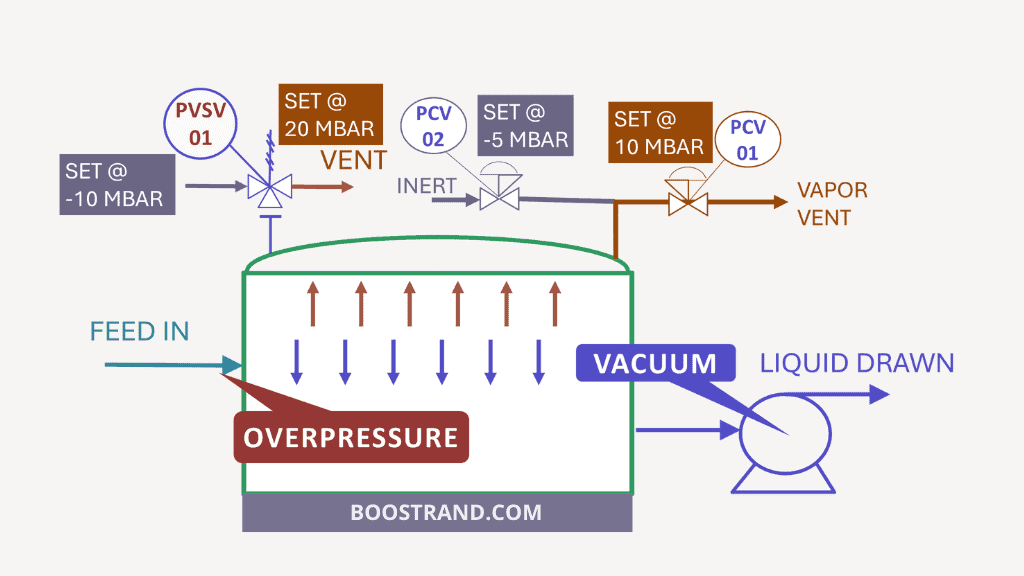

Pressure in the tower

The tower pressure is an important factor affecting the relative volatility of mixture components. As the tower pressure increases, the vaporization of the tower top product (distillate) becomes more difficult. That’s why distillation operation is always preferred to be under as low pressure as possible to come with a lower number of theoretical stages.

However, this is not the case for absorption operation, which favors a high pressure as gas solubility in a solvent increases as pressure increases.

This means that the deviation of the tower operating pressure from the pressure on which the tower was specified to operate at could be an issue as it may lead to an off-spec product.

The temperature of feed and on trays

As pressure plays an important role, temperature as well can drastically affect the operation of the tower and its deviation can cause many issues. A different tray temperature means a different degree of vaporization and condensation. This means different vapor and liquid loads on each tower tray, different compositions on the top and bottom products, and may even lead to hydraulic issues. That’s why temperature should be well monitored, and any disturbance should be controlled.

Reboiler and Condenser Operation

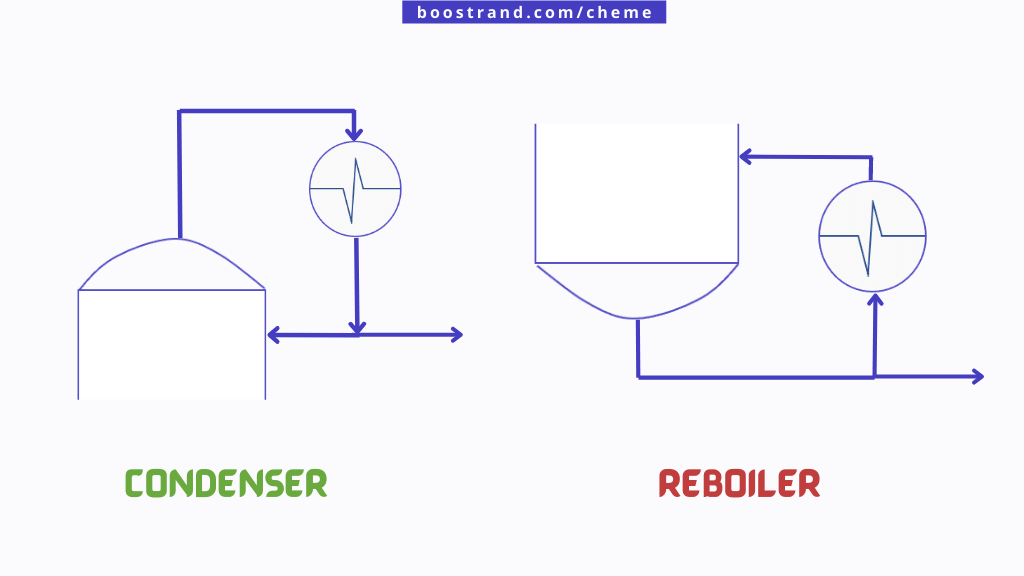

In a distillation tower, we usually have a condenser at the top. This condenser is a heat exchanger (can be a water cooler or an air cooler) that condenses the vapor from the top of the tower and returns the condensed liquid (or a portion of it in case we have a top product) as reflux back to the tower to enhance the mass transfer on the tray and increase the vapor recovery (less heavy products in the top product), which means better tower performance at the same number of trays.

Likewise, and in order to increase the separation efficiency at the bottom of the tower, the bottom liquid is introduced to a reboiler. The reboiler vaporizes a portion of the liquid with a heating medium such as steam or hot oil. The vapor formed is then returned to the tower.

The condenser and reboiler duties are considered among the most important factors affecting the operation of the tower. If they didn’t achieve the required duty, this would mean that not much liquid reflux/vapor boil-up is returned to the tower. This would mean missing liquid and vapor loads. This would lead to fewer separation efficiencies and may even lead to disturbance in tower hydraulics. If the fluid experienced much more cooling or heating in the tower (i.e., more duty), this would mean more condensation/vaporization, which may also disturb the tower profile in addition to more energy/coolant consumption, which means more operating cost.

Elevate your Process Engineering skills

Access our courses today!

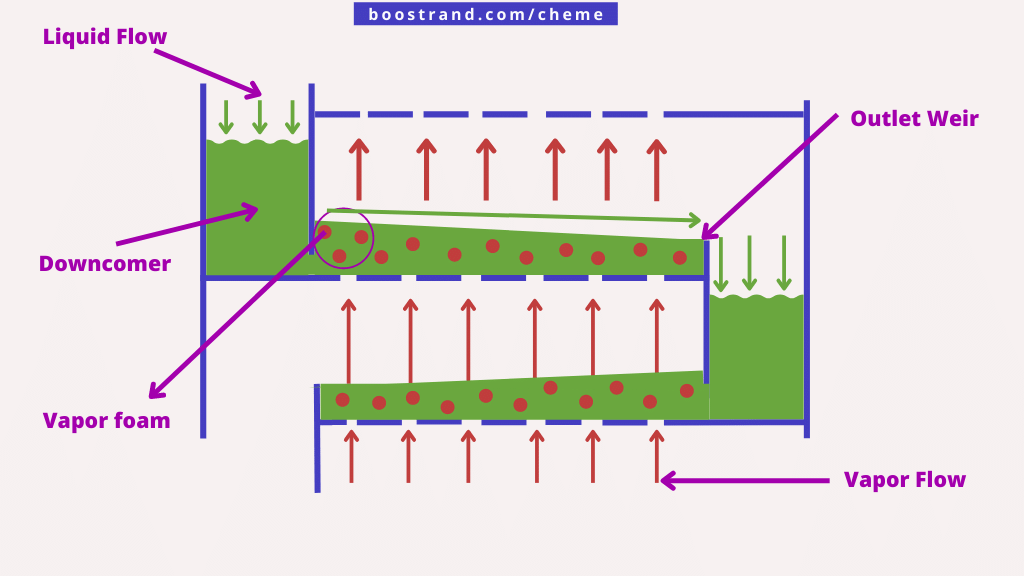

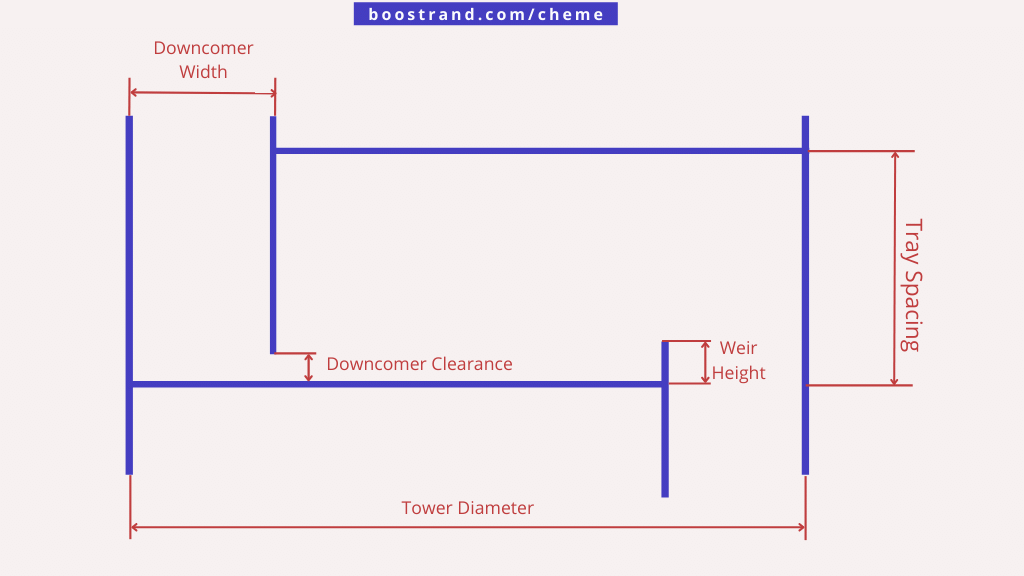

Tower Operating Region

Efficient tower operation is not just related to efficient separation, but also to tower hydraulics. Maintaining the tower in its operating region has always been a major concern. To understand the hydraulic issues that may arise from unstable liquid or vapor loads, let’s see the below photo showing the operation of the tray. The liquid comes from the top tray through a downcomer, it then passes from the downcomer to the bubbling region where it meets the vapor coming from the bottom through the tray holes. Some liquid is accumulated by a weir at the end of the bubbling region. Excess liquid moves from the top of the weir to the downcomer of the bottom tray, while vapor passes the accumulated static head to the top tray.

So, we are talking about a tray with vapor entering from its bottom to the top tray and liquid that is moving from the top tray to the bottom tray. At each tray, there is some liquid static head. The vapor needs to overcome this head and move upwards, so its velocity shouldn’t be too low.

On the other hand, the velocity of the vapor shouldn’t be too high as it shall lead to entraining liquid with the vapor to the top tray.

That’s why it’s always important to understand how changes in the liquid and vapor load profile on trays can affect them. This means that we need to consider a tray design that can handle as many disturbances as possible.

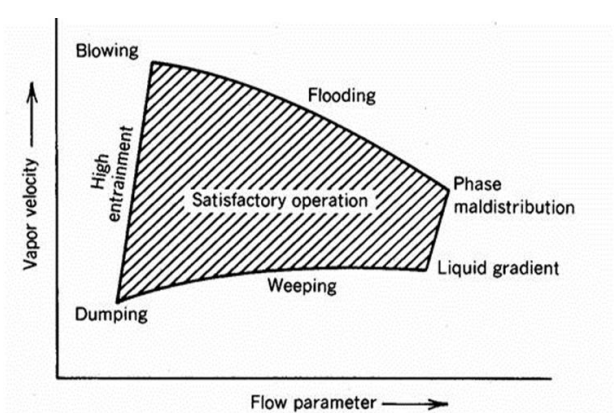

The below chart shows the preferable operating region of the tower without hydraulics issues. So what are these issues:

- Weeping: when we have too much liquid against low vapor loading, the liquid will pass down from the tray holes without having enough residence time in the tray.

- Entrainment: when vapor velocity is too high that it entrains liquid from the bottom tray to the bottom tray

- Flooding: This can occur if the liquid is accumulated in the downcomer such that level is accumulated in the top tray. It can also happen in case of high foaming on the tray that transfers to the upward tray, or due to a very high vapor rate that causes huge liquid carryover to the above tray.

Tower Design Parameters

Tower design should consider that the liquid and vapor velocities on the tray shall never cause deviation from the tray operating region. There are many factors that would affect the tower design and hydraulics such as:

Tray Spacing

Tray spacing is the vertical distance between trays. Its default value is 0.6 m. In general, a high tray spacing reduces the probability of entrainment and flooding. However, this means greater tower height.

Tower Diameter

Tower diameter expresses the capacity of the tower. The tower should have enough diameter to handle the liquid capacity. However, a very large diameter, in addition to its high cost, may cause low vapor velocities which may be a reason for weeping and disturbances especially when the tower is working at a reduced capacity.

Based on tower loading on each tray, we can determine its minimum diameter. If some trays need a diameter that is much greater or smaller than other trays by around 0.5 to 1 meter, we can divide the tower into sections as we can see in this photo.

Tray Types

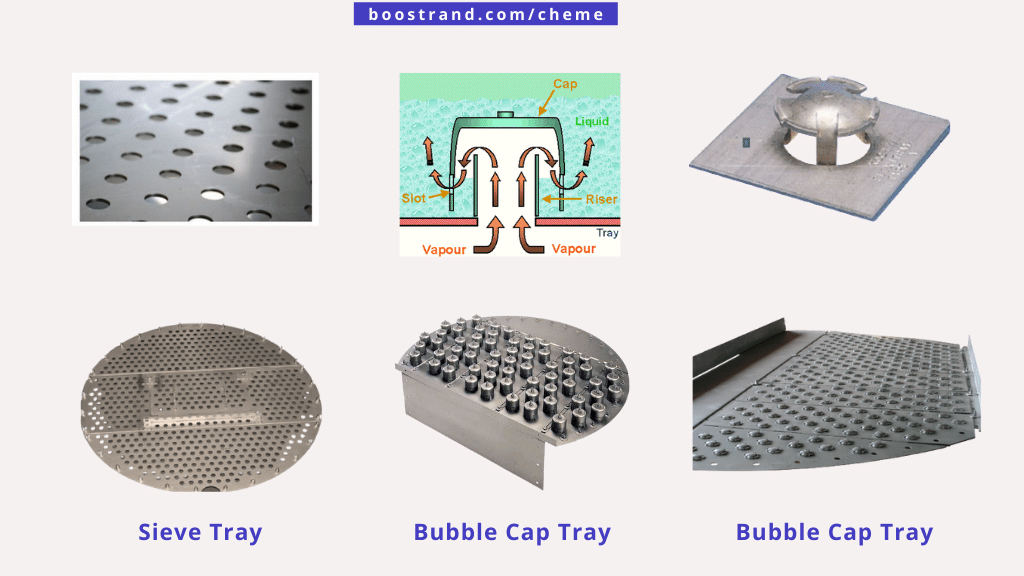

There are several types of trays. They differ with respect to their cost, operational flexibility which is the ability to handle different liquid and vapor rates, and their resistance to plugging in case of dirty service. The most common trays used today are:

- Sieve tray: least expensive. It has 50% flow flexibility, which means that tower is prone to disturbances if the capacity is less than 50%.

- Bubble Cap Tray: Most expensive, but it can work at very low turndown ratios that can reach 10-15%.

- Valve tray: It is less expensive than the bubble cap tray, and it can handle a turn-down ratio of 20-25%. It is the most used tray today.

Downcomer width

Downcomer width and clearance control the flooding ratio in the tray. Too low downcomer width would mean that there shall be a high probability of flooding. However, if we have too much width, this would mean that we have less bubbling area, which means that the vapor velocity would be too high, which can cause liquid entrainment. This means that we would need to increase the tower diameter if the downcomer width cannot be reduced.

Weir Height

As we stated above, each tray has a weir. The weir height should be adjusted and optimized. Too height weir would mean an excessive pressure drop per tray, which would mean that the tower pressure at the bottom would build up causing a higher pressure and temperature and may cause disturbances in the tower. However, if we reduced the weight height to a very low value, there will not be enough mass transfer contact between the liquid and vapor on the tray.

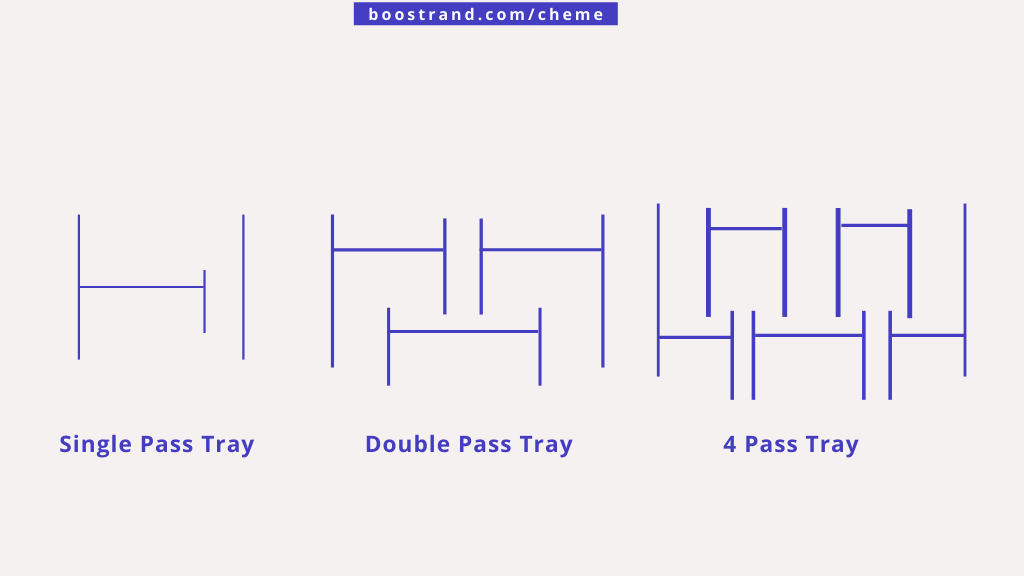

Number of passes

When the calculated diameter of the tower is large, we can increase the number of tray passes. This means that we adjust the liquid velocities by distributing it through more than 1 downcomer. This can result in less diameter, which means less tower cost. Increasing the number of passes can be feasible when the tower diameter is more than 1.5 meters. This can be checked more with the tower internals manufacturer.

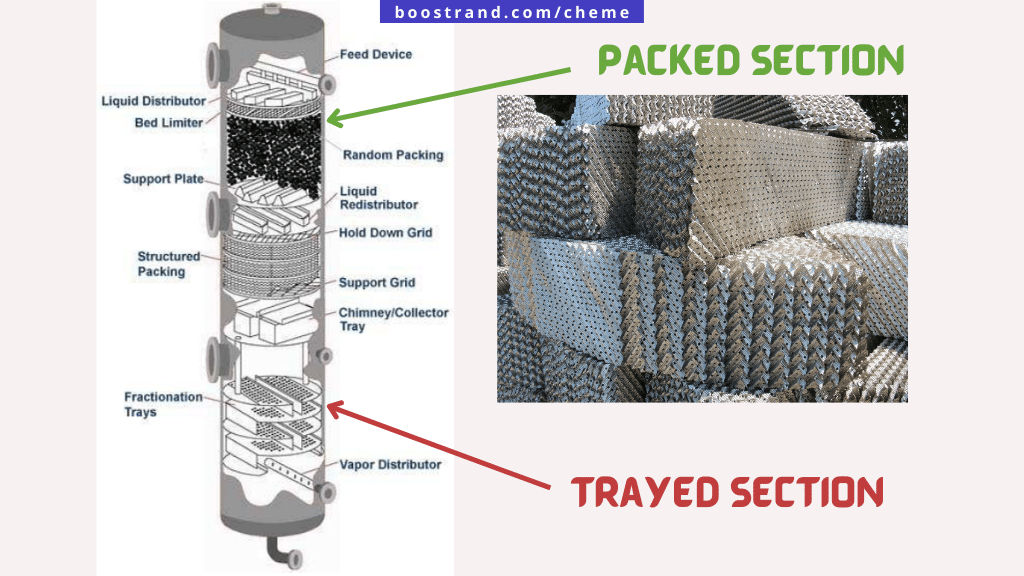

Tray vs Packing

In some cases, packing may be used instead of trays. In a packed tower, it is filled with small ceramic pellets that provide a great mass transfer area as we can see in the photo. Packed towers are commonly used when we have a very small tower (diameter less than 1 meter), when we need a very low pressure drop, and when the liquid vapor mixture is highly foaming.

Conclusion

Towers design needs to consider multiple factors in order to ensure a smooth operation. That’s why we always need to take the tower data with much care and to ensure that the design handles multiple operating scenarios such as a greater or a less capacity, different feed, different product specs, different vapor or liquid loads, ..etc. In these cases, tower hydraulics needs to be studied in order to ensure a smooth operation.

Start your Career

Access Process Engineering Introduction Course

Share this:

[…] creation of a PFD is typically based on the output of process simulation software. We have discussed plant simulation’s role in a project in the previous article. In a nutshell, process simulation involves using specialized software to model and analyze the […]