Introduction Pumps are an essential component of many industrial processes. They are used to transfer fluids from one location to another, and their performance is critical to the efficiency and safety of the process. When the operating conditions of a pump change, it can have a significant impact on the pump’s performance. In this article, […]

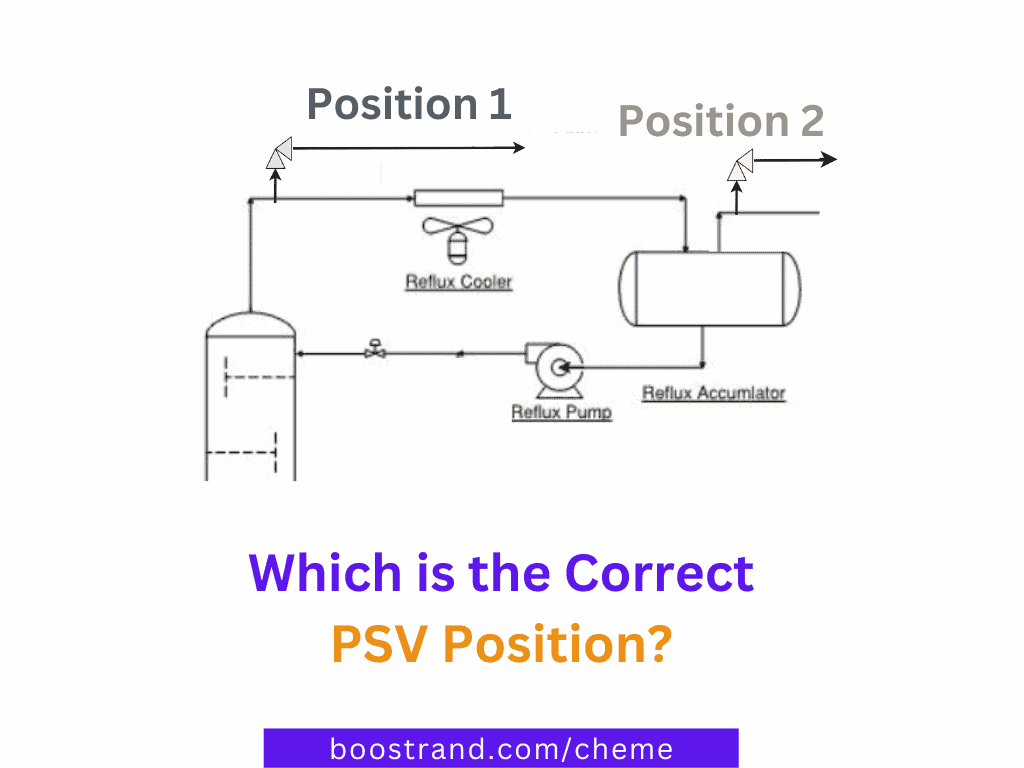

Ensuring the proper functioning of a chemical or oil and gas plant involves countless steps and precautions, but one of the crucial elements is the correct positioning of Pressure Safety Valves (PSVs). Designed to release excess pressure within a system, PSVs act as a safeguard against potential hazards such as explosions or equipment failure. However, […]

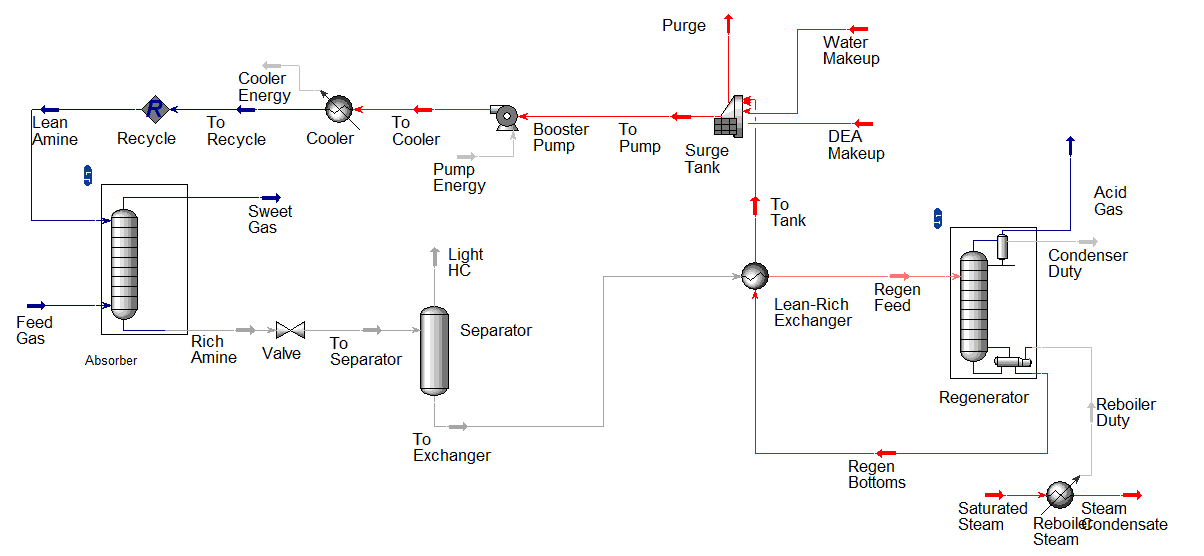

Transforming natural gas into a product that meets commercial standards and safety requirements involves removing various impurities. The first impurity that is commonly removed is related to acid gases. Acid gases are mainly carbon dioxide (CO2), and hydrogen sulfide (H2S). This process of removing acid gases from natural gas is called gas sweetening. The most […]

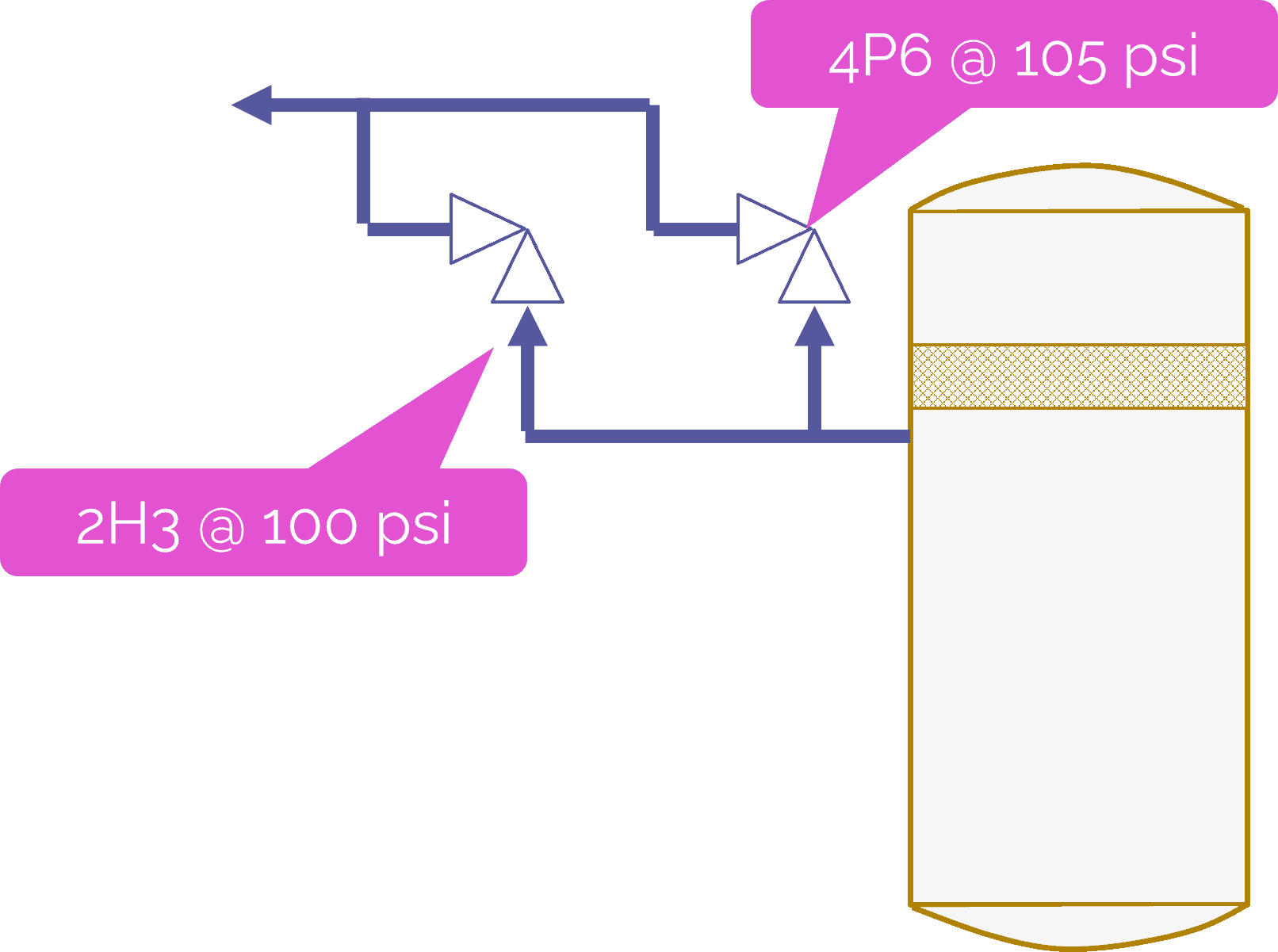

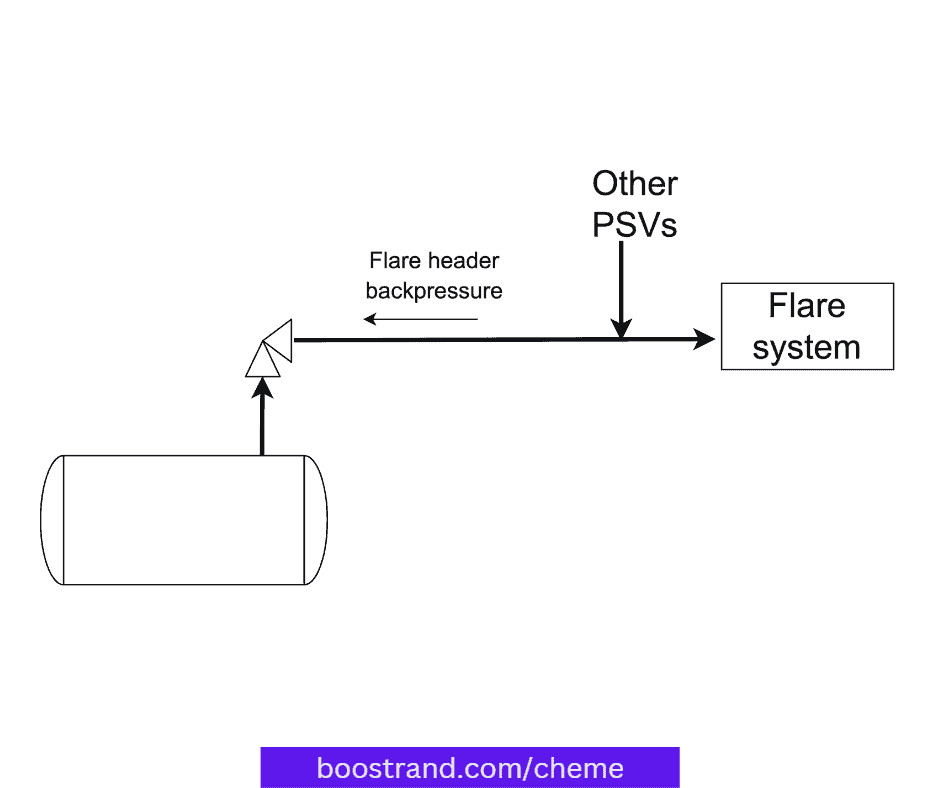

As we discussed in a previous article, Pressure Safety Valves (PSVs) play a crucial role in maintaining safe operations in chemical process engineering by protecting equipment from overpressure conditions. Due to their high importance and criticality, we should have a clear understanding of the parameters that highly affect the PSV operation and minimize their issues […]

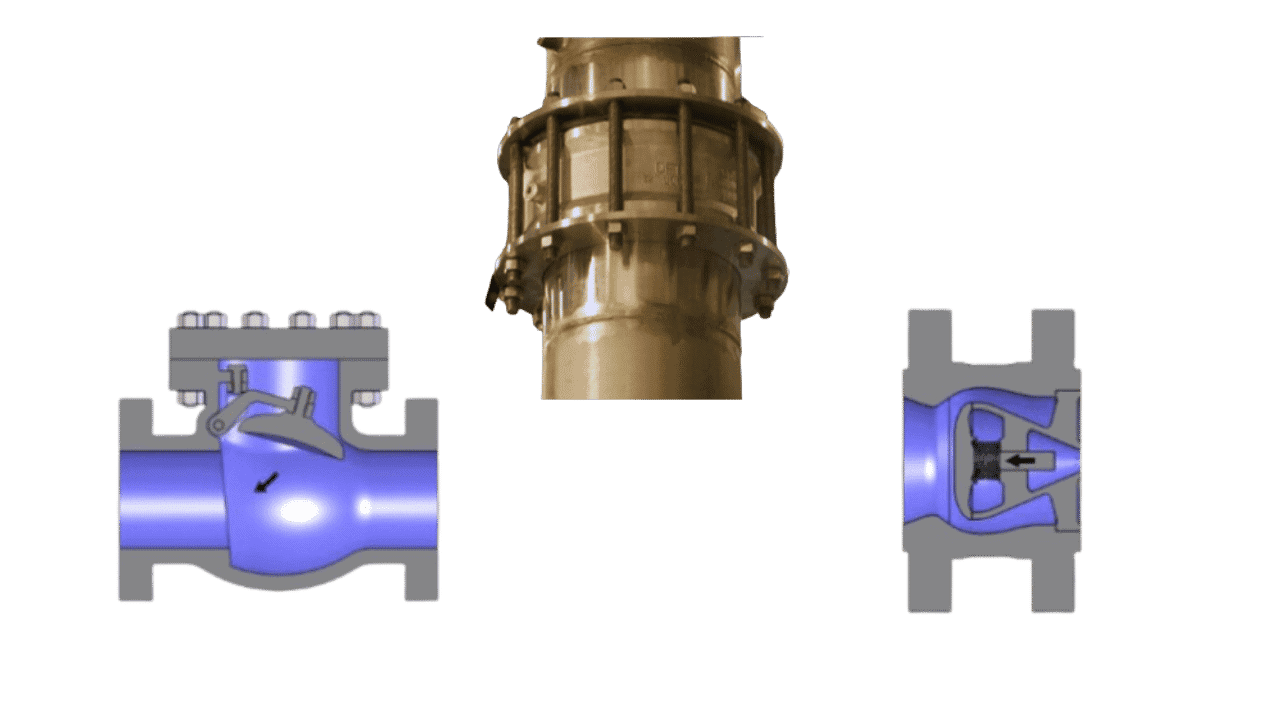

Check valves play a pivotal role in industrial piping systems by providing critical backflow prevention, ensuring that processes continue to operate efficiently and safely. However, when carrying out engineering activities, a process engineer should recognize his needs and the main issues the system might face. Based on these issues, the process engineer may add additional […]

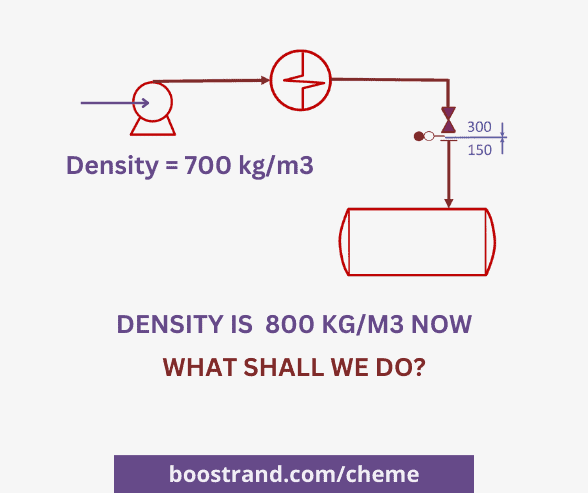

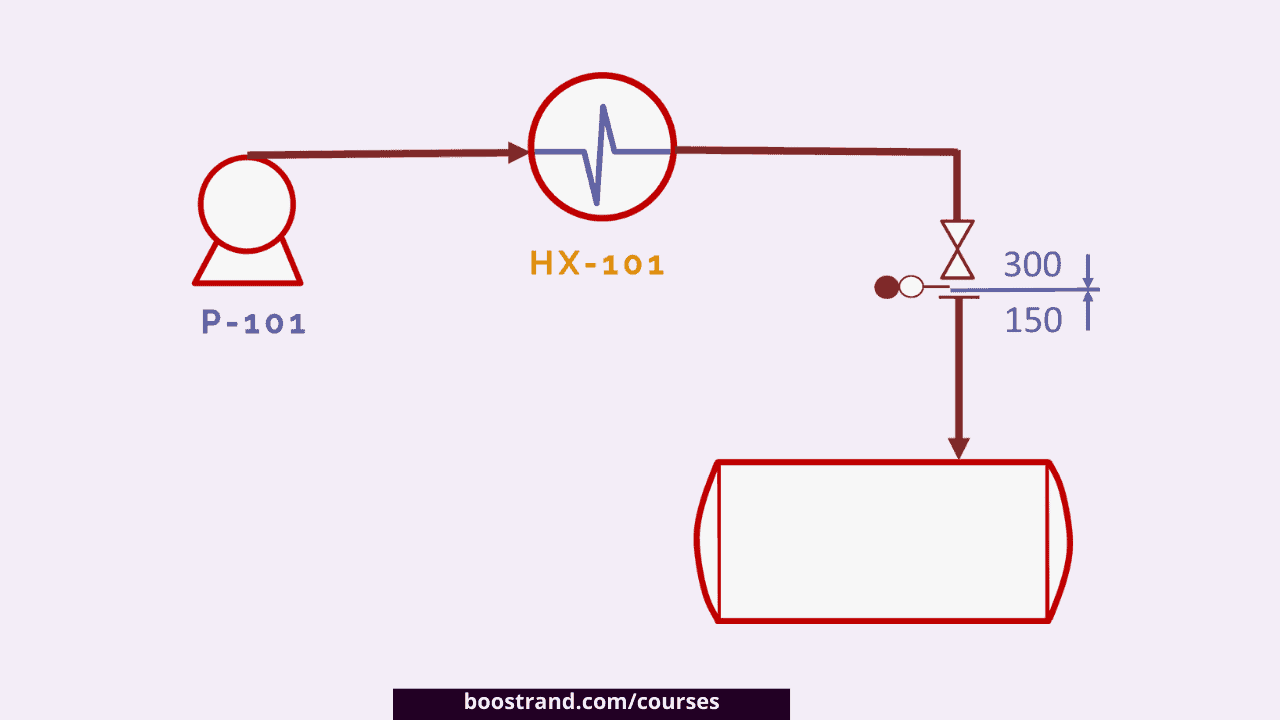

Background In the design of a new petrochemical plant, a centrifugal pump (P-101) was added to circulate the feedstock through a series of downstream equipment, including a heat exchanger (HX-101), which was critical to the operation. The pump was selected based on the process requirements, its main specifications were made based on basic hydraulic calculations. […]

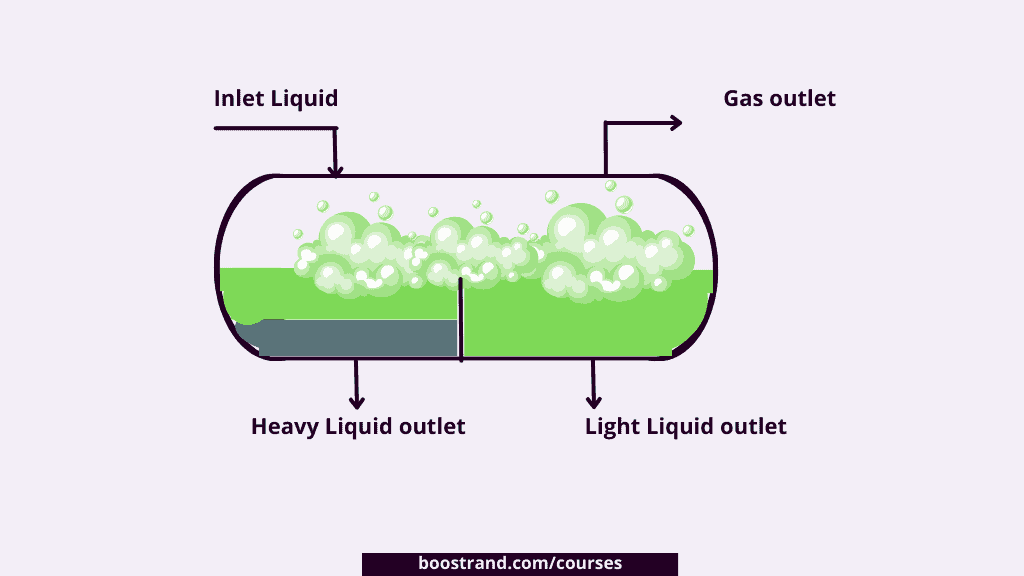

In a 3-phase separator at a crude oil production facility, operators started to notice that there were frequent overshoots in the level reading. In addition, as the gas is sent to a compression system, it was noticed that the downstream compressor suction scrubber started to receive more liquids than usual. Remember that the compressor suction […]

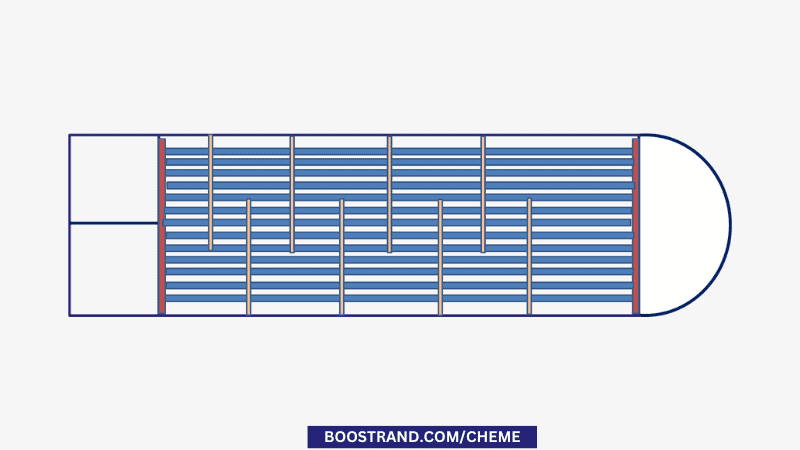

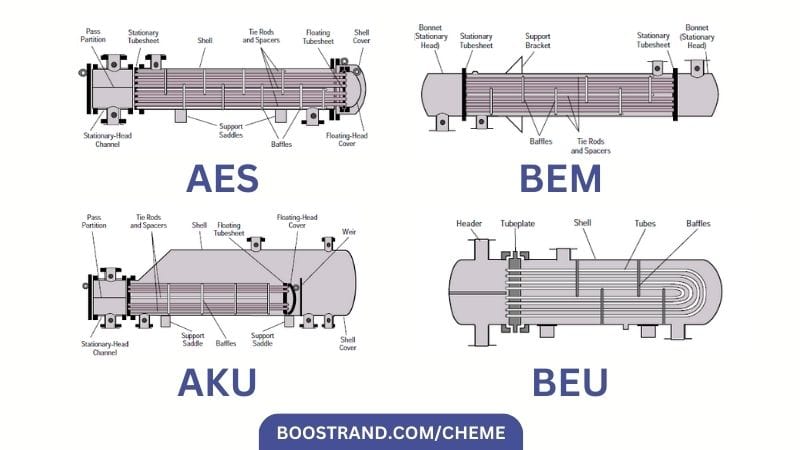

Shell and tube heat exchangers are the backbone of many industries, offering a versatile solution for heat transfer processes. If you went through any refinery or gas plant or chemical or petrochemical plants, you must have seen plenty of shell and tube exchangers. In this article, we shall go through the core aspects of optimizing […]

Introduction In any oil facility, gas plant, or chemical or petrochemical plant, pressure safety valves (PSVs) play a crucial role in preventing damage and ensuring the safe operation of plant components such as equipment or piping,..etc. While their function might seem simple, their selection, sizing, and operation involve a myriad of factors that require careful […]

Introduction Choosing the right heat exchanger for your specific service is a critical decision that can significantly impact the efficiency and cost-effectiveness, operation, and maintenance of your shell and tube heat exchanger. That’s why selecting the optimum Exchanger TEMA (Tubular Exchanger Manufacturers Association) type is crucial to ensure optimal performance and easy maintenance. In this […]