So how do the changes in gas conditions or physical properties affect the performance of a compressor? You can check out this video or otherwise continue below:

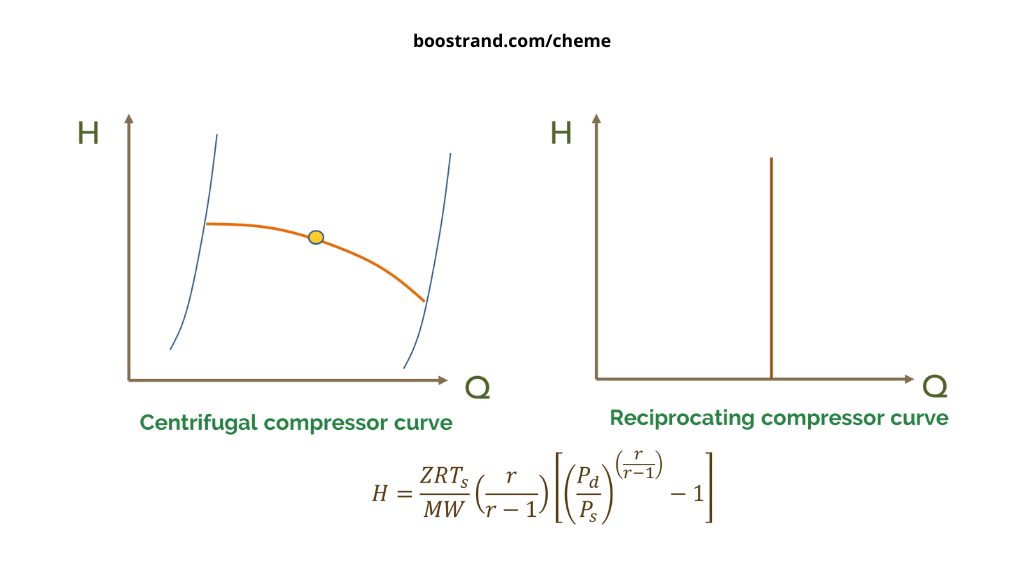

To understand this point, let’s plot the performance curve or Q-H curve of a centrifugal compressor, and the performance curve of a reciprocating compressor.

As we see, Q which is the volumetric flow rate of the gas depends on H, the head which the compressor gives.

Let’s assume that we need to operate the centrifugal compressor at this point, so we have a specific flow rate at a specific head. For a reciprocating compressor, it shall give a constant volume so we shall have a constant volumetric flow rate, but head can be variable.

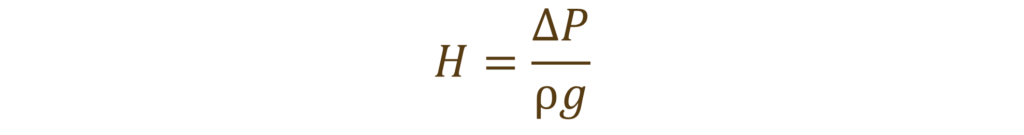

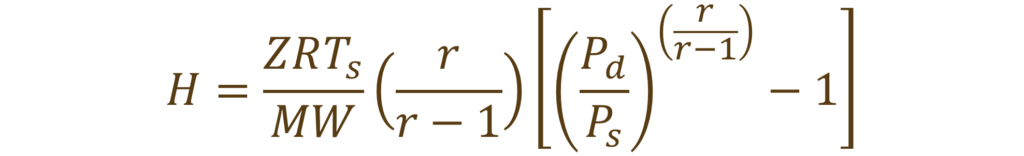

For a pump, the pump head has a simple relationship with the differential pressure as the liquid density is constant.

But for a compressor, and as gases are compressible, we shall have a much complex relationship as the gas physical properties change with the change of pressure and temperature. So this shall be the relationship between head and pressure:

Effect of Change in Suction Temperature

So for example, if we want the same gas discharge pressure at a higher suction temperature, this means that we need that the compressor gives a higher head.

Discover Compressors as a Process Engineer

Discover main compressor types, performance curve, surge / stonewall issues, capacity control for different compressor types.

This may lead to decreasing the inlet flow rate for a centrifugal compressor, while in case of a positive displacement compressor, the flow rate is not expected to decrease as we can see in the curves, but this still means more power and motor rated power needs to be checked.

And this is a nice feature of positive displacement compressor as they are much less affected by gas conditions and characteristics than dynamic compressors. But still high suction temperature means higher discharge temperature, API recommends that the maximum operating temperature of a reciprocating compressor is 150 C.

Effect of Change in Gas Molecular Weight

The opposite case will be when we examine the gas molecular weight, we may have some modes of operation where we need to compress gas with a higher molecular weight, which means a higher density.

So if we need just to maintain the compressor discharge pressure, this shall need less head, which means more compressor throughput, and vice versa for a low gas molecular weight, which means higher compressor head and less flow at constant discharge pressure.

For a positive displacement compressor, still, not much flow change is expected but means more pressure and more power.

What If we want to keep the gas flow rate constant?

On the other hand, we may need to keep the flow, which means that the compressor still gives a constant head, but the outlet pressure varies.

So when the suction temperature increases at a constant head, the compressor will give less discharge pressure, while when we have a gas of a higher molecular weight, the compressor will give a higher discharge pressure at a constant head.

Discover Compressors as a Process Engineer

Discover main compressor types, performance curve, surge / stonewall issues, capacity control for different compressor types.

As the compressor curve depends on many factors, it’s always important to provide the compressor manufacturer with the applicable scenarios to check them.

For this reason and as the API 617 recommends, the supplier provides the curves for both head vs flow rate and discharge pressure vs flow rate.

If you want more information on compressor operation and performance, you can check out our Compressor Operation for Chemical Process Engineers course.

Start your Career

Access Process Engineering Introduction Course

Share this:

[…] creation of a PFD is typically based on the output of process simulation software. We have discussed plant simulation’s role in a project in the previous article. In a nutshell, process simulation involves using specialized software to model and analyze the […]