Digital technology has been growing so fast. With the new technologies introduced today, we now have many options that will make our life much easier.

This means much better productivity, fewer errors, easier access to data, and better communication means.

All this shall lead to reducing fixed and operating costs, and achieving the target in much less time.

That’s why digital transformation is a growing trend today in different sectors, this for sure includes the oil and gas sector, and chemical engineering career in general.

You can watch the content of this article in the below video. Otherwise, you could continue reading below.

WHAT IS DIGITAL TRANSFORMATION?

So what is digital transformation about?

Digital transformation is the process of using digital technologies in the workflow. This would mean applying the new technologies in our daily tasks. This would lead to a smoother workflow and a more efficient process.

Applying the new technologies can either be through enhancing the existing workflow or creating totally new workflows.

This can be through applying technologies related to data analysis, artificial intelligence, write a script to automate our routine tasks, create apps to perform our workflow, this can be either through the web, the desktop or even a mobile device.

We can apply internet of things technologies through devices that connect to cloud servers, apply complex algorithms and take decisions without the need for human intervention. There are even other technologies that can be used.

Chemical Engineers Pain Point

But why do we need to apply digital technologies as chemical engineers?

There are many challenges that chemical or process engineers or even engineers in general face in their daily work. This may be seen in different sectors, whether we are talking about engineering design and projects sector, whether it is related to operations and maintenance of assets in a plant or a facility, or even in the research sector.

We experience different types of tedious tasks done manually through copying and pasting scattered excel sheets, taking a lot of time to search for information, to prepare a document, to look for the history of a specific issue, .. etc. All these types of tasks consume a lot of time and the probability of making mistakes is relatively high.

What I mean here is that we have plenty of issues in a typical workflow that depends on human intervention. Many of these are tedious tasks that take a lot of time and there is a probability of making mistakes that can cause losses in time, assets, and money. Here comes the importance of digital transformation.

Digital Transformation is Already Here

So how would digital technologies solve these issues? Actually, the rapid development of technology is clear in our life. This has even been much more touchable during the Covid 19 lockdown.

People started to work from home, use apps like Zoom and Microsoft Teams to communicate with each other, use cloud platforms to have common access to files and services and even use apps like Trello or Microsoft Planner to distribute tasks and help organizing the workflow. People can remotely access remote data or devices through different technologies. Data are stored in cloud storage services as Google Drive or OneDrive with multiple sharing options between team members.

These are general examples of how digital technologies are already changing our lives now.

But what if we had more personalized solutions to specific issues related to our tasks? We can start creating apps related to our daily tasks, we can write a code to automate typical Excel work, we can use internet of things to install devices in places that are difficult to access, we can use artificial intelligence and machine learning to identify operational issues and take decisions that are data driven. There are endless solutions. We shall see some below.

Automate Repeatable Tasks

If the issue is related to tedious tasks which are systematic and have their own rules and take a lot of time, then we can automate these tasks using some programming skills to write a code. Through running this code, the task could be done with a button click.

Python Scripts

This can be done by a Python script or by any other programming language. Python has become the most used language because of its easy syntax, and the support of many applications, so it can be used in web development, desktop apps, data analysis, machine learning and artificial intelligence. That makes it a nice choice when writing automation scripts.

Running a script may not be user-friendly as we are not expecting users are to set up environments on their devices, that’s why in many cases the script needs to be wrapped in a desktop app.

VBA Macros

Or, if all the task is related to Excel spreadsheets, it can be done by an Excel VBA macro, although VBA is a primitive language that hasn’t been updated since 2004, this has even been one of the simplest solutions. But being embedded in Excel eases running it on any computer. No need for complex environment setup or installing additional software which is a good advantage if we want a quick solution. Even if someone doesn’t have coding skills, he can record a macro. I have made plenty of VBA macros that helped me a lot automate tasks.

Automate your Engineering Work

Understand how to use Excel VBA to automate your code

It’s important to highlight here that Microsoft is now availing of creating scripts on Microsoft Excel using Javascript. Javascript, unlike visual basic, is a modern language that is extensively used in web, mobile, and even desktop applications. Also, Microsoft is providing a built-in nice code editor. However, up to this moment, it is available only for the Office business plans and only in the web version, so it is not available in the Excel desktop app. This makes its accessibility still much more difficult to use and apply to all users than VBA. But maybe this will change in the future, and I hope so.

Microsoft Power Automate

There are also other automation techniques nowadays. For example, Microsoft now provides Power Automate, which was formerly called Flow. This can automate some tasks between different apps. This can manage approval processes and send notifications automatically. It can even be customized to run scripts on Excel when a certain event triggers.

Microsoft Power Apps

More integration can even be made using Microsoft Power Apps which can build web and mobile apps to ease the accessibility of the workflow. I believe this combination can help a lot in automating tasks, but we shall wait and see.

Automation can drastically reduce the time of performing the tasks from days to hours or even minutes. It can help focus on taking the right technical decisions and hence reduce mistakes or even eliminate them.

One Source of Truth

One of the issues people face in their tasks is that information is scattered among different files. People take a lot of time opening many files and getting these information. We may find ourselves working on a copy of a file which is not updated. We may discover that some information is present in some emails which are not distributed to everyone. This causes lots of conflicts and contradictions which means more time, more errors and may be more cost.

So what if all the information is stored in one database. Any update is directly reflected into this database and everyone has access to the database, they can directly access the information from a simple user interface. In this case, we shall have one source of truth. Data will be much more accurate, people can reach it more easily. We shall save a lot of time or even money that may result from mistakes due to the contradiction mistakes that were avoided.

What if this data was stored on the cloud, they can even be more accessible to people who can access it from anywhere. People can work remotely and can solve issues even if they are not physically available.

Create Apps

So we can automate our works using scripts, we can unify our source of information through databases, we can let it be accessible from anywhere using the cloud.

We need to connect all these technologies together in a nice user interface that is easy to use, can access the database, or have some kind of interface with it.

This can be done by creating an application.

Applications can be accessed through the web, or mobile, or desktop.

Web and mobile apps are getting to grow because they help access the service we need remotely and enhance the user experience in general.

Through the app, we can either query the data we need or add or update or delete the existing data. Anyone who shall do the task shall have access to the updated data. He doesn’t need to open any other file or email and copy or paste from here and there.

If the data is hosted on the cloud, this means that this app can even be web-based or mobile-based, anyone can access it from anywhere, this can help accelerate the workflow and make sure all the team has the same understanding even if they are working remotely.

Use AI and ML to take Decisions

Digital technology may not just be used to automate tedious tasks or unify the source of information. Their role can be much greater. It can be extended to implementing machine learning and artificial intelligence to make decisions.

Through artificial intelligence, the computer system or robot would be able to perform tasks that require human discernment or intelligence. We already see how many examples of artificial intelligence as self-driving cars, understanding human speech as in the case of Apple’s Siri for example.

Machine learning is considered a branch of artificial intelligence.

Through machine learning algorithms, we can exploit the data we have to build complex models that can make predictions and give insights based on the data in hand. As the model is fed with new data, it keeps on having more accurate predictions.

One famous example of artificial intelligence is used by social media apps such as Facebook where it uses the user’s data to show up the content he will probably react with or personalize the ads based on his interest to increase the probability of clicking it.

And As the user keeps on opening Facebook, likes, or shares a specific content, the machine learning model is fed with more data, so the prediction of the content he may like or be interested in will be more accurate. Another famous application is image recognition, as the machine learning model is fed with more data, it can recognize more images accurately.

To enhance plant operation, based on the available log data, machine learning algorithms can predict the expected equipment failure or process upset conditions that may lead to unexpected shutdowns before they happen. This can give the operators the time to respond to operational issues or adjust their maintenance schedules.

This can lead to reducing the probability of unexpected shutdowns and enhancing the performance and lifetime of the equipment. This simply means more production rate, more profit, and reduced cost by avoiding equipment failure.

Using IoT and Cloud Services

But how would the data be delivered to servers running machine learning and artificial intelligence algorithms?

This can be done using the IoT which is the internet of things technology. Through devices that can have access to the internet, these devices can be sensors or instruments in our case, data can be sent and stored in the cloud.

Cloud technologies are developing very fast as Amazon, Microsoft, and Google are immensely investing in them. This made them very reliable and have great capabilities. We can now see Amazon Cloud Services, Microsoft Azure, and Google Cloud as the 3 main cloud suppliers in the world.

So the cloud database can store the data supplied from IoT devices, the cloud servers can then perform the required computing and algorithms and send notifications to the team to warn them of expected issues and actions needed. This can be made in a simple user interface that can even be accessed from anywhere, remember we are talking about cloud storage and computing.

By applying personalized algorithms along with cloud computing and IoT devices, the plant operation can significantly enhance its performance, reduce costs which means maximizing profit.

Solve Complex Problems Using Python and Matlab

Using a software to solve complex problems may not be something new, as chemical engineers have been relying on software programs as HYSYS or Aspen Plus or PROII or HTRI,….etc.

But through writing a code, we can solve complex differential equations and apply complex procedures

We can utilize tools like Matlab. We can also use Python, which is open source, unlike Matlab, and is supported by many packages for this purpose. This may be more useful in research tasks.

Solutions for Engineering Sectors

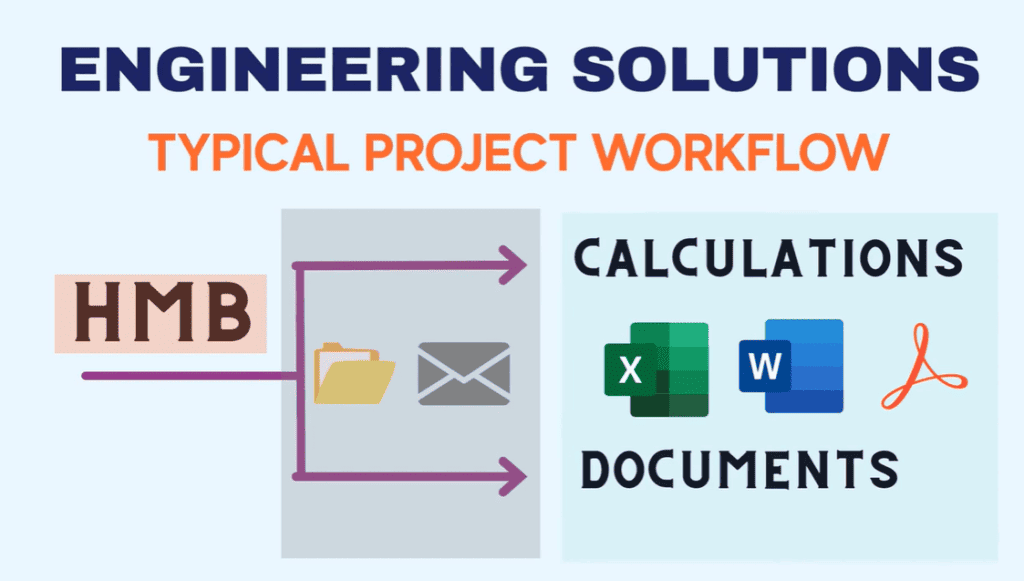

So let’s talk more in deep and see some about how digital solutions can affect the engineering sector. The engineering sector is mainly based on projects. This starts in the design phase, where we need to prepare a basic design of a new plant or a unit or even to add some modifications to an existing unit.

In this phase, a process engineer is requested to prepare a process flow diagram with a heat and mass balance that contains all the design data that shall be used to size the equipment, instruments, and pipes.

Calculations are usually made in separate excel sheets, then the outcome of the calculations is reflected in datasheets or tables containing the data needed to be sent to vendors and manufacturers as the requested equipment size, operating and design conditions, fluid properties,…etc.

So we are talking here about a complex workflow that needs a lot of care as mistakes could lead to losses in project cost and time. In addition, it contains lots of tedious tasks, for example, the material balance data may have more than one mode of operation, there maybe 5 or 10 or 20 modes of operations and scenarios the designed plant is expected to work at.

How would we ensure that the designed equipment is taking all scenarios into consideration? How would we ensure that all the documents are free of mistakes that could be trivial copy and paste mistakes? How could the calculations and document preparation be carried out without taking a lot of time that could affect the schedule?

I believe that digital technologies can help a lot in this field. Let’s see how.

Use Excel Macros

The first and fastest solution to many tedious tasks is related to Excel macros. This is because most of the calculation sheets and documents are already based on Excel.

Through macros, we can manage input data transfer from the heat and material balance to calculation sheets. We can get the data and recognize the controlling cases easily with a macro.

We can also use macros to make the calculation sheet more efficient, detect user input mistakes and give insights to the user of any issue in the calculation outcome.

Automate your Engineering Work

Understand how to use Excel VBA to automate your code

Manage the transfer of the outcome of the calculations to the datasheets to be sent to vendors.

Of course as I said, other tools may be used like Python scripts for example, but as Excel macros are easy to use and there is no need to setup a special environment as in case of Python, which won’t be applicable for most users, I think that Excel macros win in this case.

Create an App for your Project

However, the macro solutions are considered as preliminary solutions that are limited to solve some tedious tasks. Still there are other issues such as not having one source of truth. We usually have separate files that may be duplicated or replaced by updated versions or not sent to all the team. So we still need more from digital technologies.

What if we replaced Excel calculation sheets with a user interface that imports the data directly from material balance, perform the required calculations and exports the outcome to the datasheets?

Instead of having multiple files prone to conflict issues, we can store all the project data, either from the material balance or the calculations or the datasheets in a database that shall be the only source of truth.

There are now solutions like Aspen Basic Engineering and AVEVA Unified Engineering that can give this type of service. They can even integrate with the simulation software.

The user then can access all the data from a dashboard that he can access either from the browser or from an app. He can do all his job and access the data he needs from one dashboard.

And as explained before, if the database is stored in the cloud, this would even mean better accessibility, any member of the team working remotely can access all the project as if he is at work premises.

If any of the data is updated in the database, all the team would be notified. Any impact on calculations or datasheets shall be clear to the whole team before it is too late. This will ensure better team better project efficiency through saving project cost and time.

Pain Points Plant Operations Sector

So we have given a quick example of how we can use digital technologies in the engineering sector.

What about the plant operation? How would digital technologies help?

Well, in plant operation we have tons of data. Instruments keep on sending signals and readings for the plant parameters 24/7. Operating personnel use spreadsheets to manually track the performance of their plant, getting some information in many cases is difficult to be accessed by many people, a lot of time is taken to prepare reports and send it to management, tracking the equipment or asset state or conditions leading to shutdown is not easy.

What if this data was better exploited using data visualization, machine learning, and artificial intelligence?

What if this data was democratized among the whole operations team so that it would be easily accessed and searching it would be easy?

If we applied machine learning to the data we have, we can even detect issues early. This can prevent asset or equipment failures and unexpected shutdowns, which means lots of cost savings.

So how would this be applied? Let’s see.

Solutions to Plant Operations Sector

Through data visualization, all the team can access the plant data using a dashboard from anywhere in no time. This would help better supervision, problem-solving, and easy detection of operational issues.

In the dashboard, plant key performance indicators (KPIs) can be clearly displayed, reports can be automatically generated, trends of different process parameters can be easily accessed, and process upsets or spikes are easily detected.

Through this dashboard, direct notifications can be sent to operating personnel of predefined issues, which can help fast response against any operation upsets.

Data visualization is not the only solution that can be provided, but we can even leverage the functionality of such a system using artificial intelligence and machine learning. Through machine learning, we can use the previous data trends to predict the probable issues before they happen.

Automate your Engineering Work

Understand how to use Excel VBA to automate your code

We can see for example that a plant shutdown occurred when a temperature rise occurred in a specific trend, now the model records this trend and if this trend was repeated, it can warn the personnel of an upset before it happens. Operating personnel would have the time to respond before a shutdown occurs, preventing an unplanned shutdown.

Through applying machine learning models, we can detect the trends leading to equipment failure, heat exchanger fouling, or plant shutdown. Instead of applying scheduled maintenance whether the plant really needs it or not, the maintenance can be predicted, which means more efficient maintenance and less shutdown time, energy and cost savings, and a happy team.

There are now companies providing such solutions as AVEVA, TrendMiner, Innovyze, etc.

Conclusion

So as we have seen, there are lots of promising digital solutions that can be applied in different sectors related to the chemical engineering career. Applying a lot of these solutions may not be easy, it shall take time to apply them and to get different teams familiar with them. But in the end, they are really worth trying, and their benefit shall pay off in the long run.

Start your Career

Access Process Engineering Introduction Course

Share this:

[…] creation of a PFD is typically based on the output of process simulation software. We have discussed plant simulation’s role in a project in the previous article. In a nutshell, process simulation involves using specialized software to model and analyze the […]