Distillation and fractionation columns are critical equipment in refining and petrochemical facilities. While tower operation fundamentals are essential—as explored in our previous article on effective tower operation—proper tray selection becomes even more important when dealing with fouling services.

Selecting the right tower trays for fouling services requires balancing efficiency with reliability. This guide helps process engineers choose appropriate column internals for applications involving polymerizing fluids, particulates, and other challenging process conditions.

Understanding the Fouling Challenge

When processing fluids prone to fouling, polymerization, or containing particulates, the choice of column internals directly impacts operational reliability. Inadequate internal selection leads to frequent shutdowns, cleaning cycles, and lost production.

The fundamental principle: prioritize reliability over peak efficiency in fouling applications. A moderately efficient tray that maintains continuous operation consistently outperforms a high-efficiency design that requires frequent maintenance.

Tray Selection for Clean to Light Fouling Services

Valve Trays: The Industry Standard

Valve trays currently dominate industrial applications, offering an optimal balance of efficiency, cost, and operational flexibility. However, their fouling resistance varies significantly based on valve design:

Fixed Valve Trays

Fixed Valve Trays represent the preferred option for fouling services:

Key Features: With a turndown ratio of 3:1, valves permanently integrated into the deck with no moving parts; horizontal vapor discharge pattern creates continuous flow

Advantages: Eliminates sticking components; prevents stagnant zones where fouling initiates; large opening sizes (SVG, PROVALVE designs) provide superior fouling resistance

Disadvantages: Slightly lower efficiency than movable valves in clean services

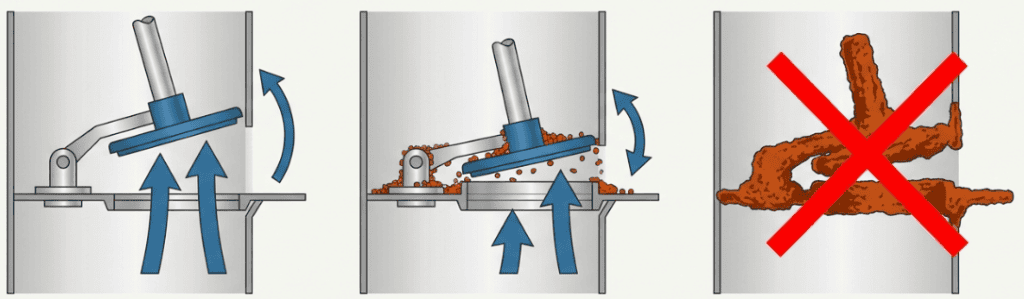

Movable Valve Trays

Movable Valve Trays should be avoided in fouling applications:

Recommendation: Use fixed valve alternatives when fouling is a concern

Key Features: Moving valve components that open/close based on vapor flow; vertical vapor discharge

Advantages: Excellent efficiency in clean services; superior turndown capability for variable flow rates

Disadvantages: Moving parts provide increased surface area for fouling deposits; valves can stick shut when exposed to polymerizing fluids or particulates; poor reliability in fouling services

Sieve Trays: Simple and Economical

Sieve trays offer the simplest and most cost-effective design:

Best Application: Stable operations with moderate fouling tendency

Key Features: Perforated plates with holes (3/16″ to 1/2″ standard; 3/4″ to 1″ for fouling services); no moving parts

Advantages: Most straightforward design; lowest cost; larger holes reduce plugging potential in fouling services

Disadvantages: Limited turndown capability (~2:1); liquid weeping at low vapor rates reduces efficiency; not suitable for severe fouling

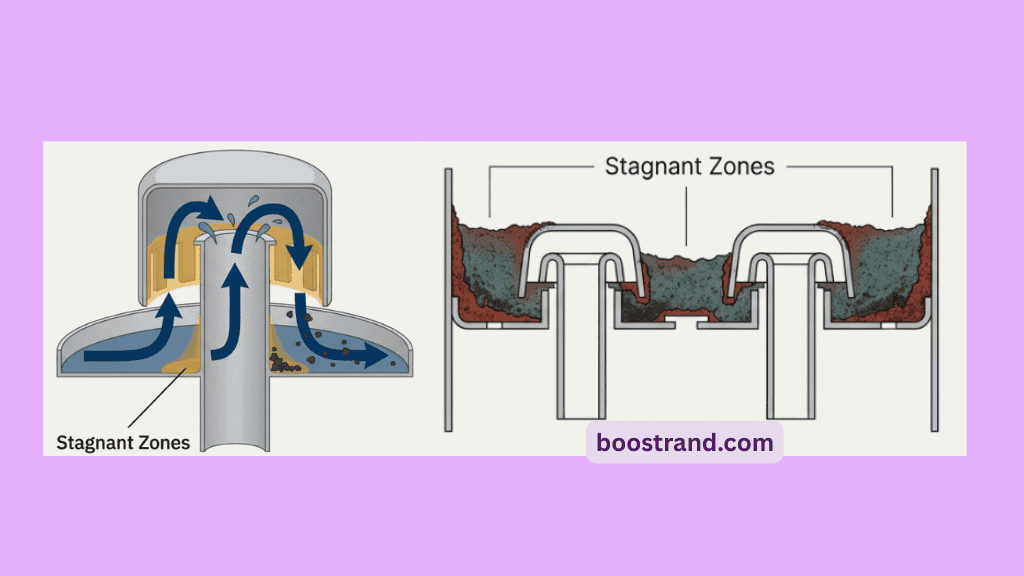

Bubble Cap Trays: Limited Application

Bubble cap trays feature elevated risers with caps that direct vapor through slots into the liquid pool. While this design provides excellent performance at low flow rates and outstanding turndown ratios (10:1 or greater), bubble caps perform poorly in fouling and polymerizing services.

Key Features: Elevated risers with caps that direct vapor through slots into liquid; complex geometry

Advantages: Excellent performance at low flow rates; outstanding turndown ratios (10:1 or greater)

Disadvantages: Stagnant zones beneath caps promote deposit formation and polymer growth; complex geometry complicates cleaning; high pressure drop increases operating costs; poor performance in fouling services.

Modern applications rarely specify bubble caps for fouling services, reserving them for batch distillation and systems with highly variable liquid loads where other tray types prove inadequate.

Dual Flow Trays: The Robust Solution

Dual flow trays deliver unmatched reliability for severe fouling:

Best Applications: Severe fouling, polymerizing, or high-solids applications (PVC slurry strippers, refinery vacuum wash sections, ethanol beer columns)

Key Features: Eliminates downcomers entirely; vapor and liquid compete to flow through same perforations (counter-current competition)

Advantages: Vigorous pulsating action continuously agitates liquid and washes underside; self-cleaning mechanism prevents deposit accumulation; maintains open flow paths in extremely dirty services

Disadvantages: Reduced separation efficiency compared to conventional crossflow trays

This counter-current competition creates vigorous pulsating action that continuously agitates liquid on the tray deck while washing the underside. The self-cleaning mechanism prevents deposit accumulation and maintains open flow paths even in extremely dirty services.

Dual flow trays have demonstrated excellent performance in challenging applications such as PVC slurry strippers and refinery vacuum wash sections. Industries processing polymerizing materials or high-solids streams routinely specify dual flow trays to avoid costly unplanned shutdowns.

Packed Columns: Proceed with Caution

Packed towers generally underperform in fouling applications and should be avoided when deposit formation presents concerns.

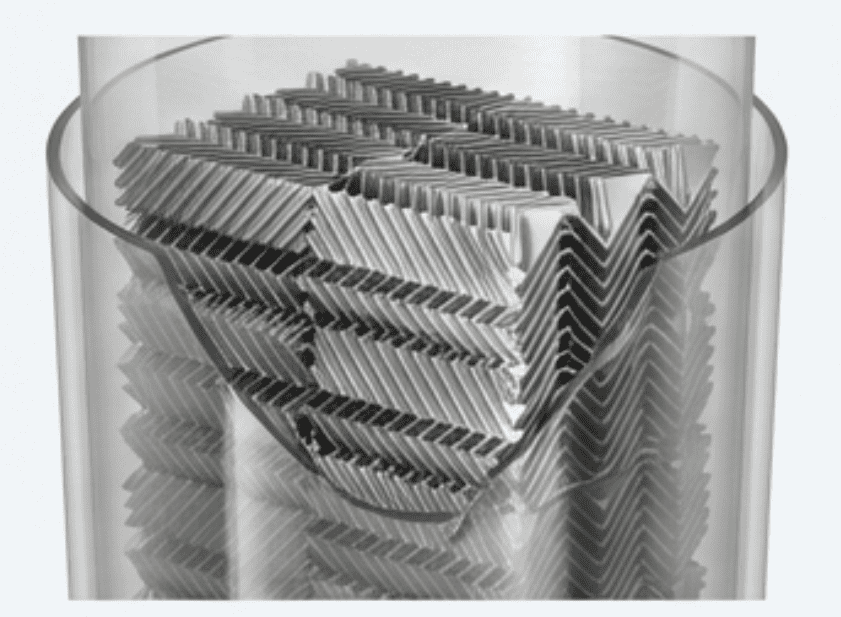

Structured packing, with its tight corrugated geometry and small flow channels, plugs rapidly when exposed to fouling materials. The compact spacing between metal sheets creates numerous nucleation sites for deposit growth, quickly compromising performance. Even minor fouling can cause localized flooding zones and dramatic pressure drop increases.

Random packing tolerates light fouling better than structured alternatives, particularly when using larger packing elements. The irregular arrangement and greater void fraction reduce plugging tendency. Nevertheless, random packing remains inferior to properly selected trays for most fouling services.

Grid packing represents the exception. These specialized structured packings feature smooth metal surfaces with large open areas specifically engineered for severe fouling, coking, and erosion resistance. Grid packings combine high capacity with low pressure drop and excellent mechanical strength. They find application in ethylene primary fractionators, atmospheric column overflash zones, vacuum tower wash sections, and flue gas scrubbers. When liquid distribution requirements can be met, grid packings offer extended run times in extremely severe services.

Making the Right Choice

Successful tray selection for fouling services requires matching equipment capabilities to process severity:

- Light fouling: Fixed valve trays or large-hole sieve trays provide cost-effective reliability

- Moderate fouling: Fixed valve trays offer the best balance of efficiency and fouling resistance

- Severe fouling/polymerization: Dual flow trays or grid packing deliver maximum reliability despite efficiency penalties

Remember that a “less efficient” tray design that maintains continuous operation generates more value than a “high-efficiency” configuration requiring frequent cleaning. Process engineers should work closely with column internal suppliers to evaluate specific service conditions, operating ranges, and reliability requirements when specifying tower internals.

For foundational knowledge about tower operation principles, including hydraulic considerations and performance factors, refer to our article on effective tower operation guidelines.

Start your Career

Access Process Engineering Introduction Course

Share this:

[…] creation of a PFD is typically based on the output of process simulation software. We have discussed plant simulation’s role in a project in the previous article. In a nutshell, process simulation involves using specialized software to model and analyze the […]