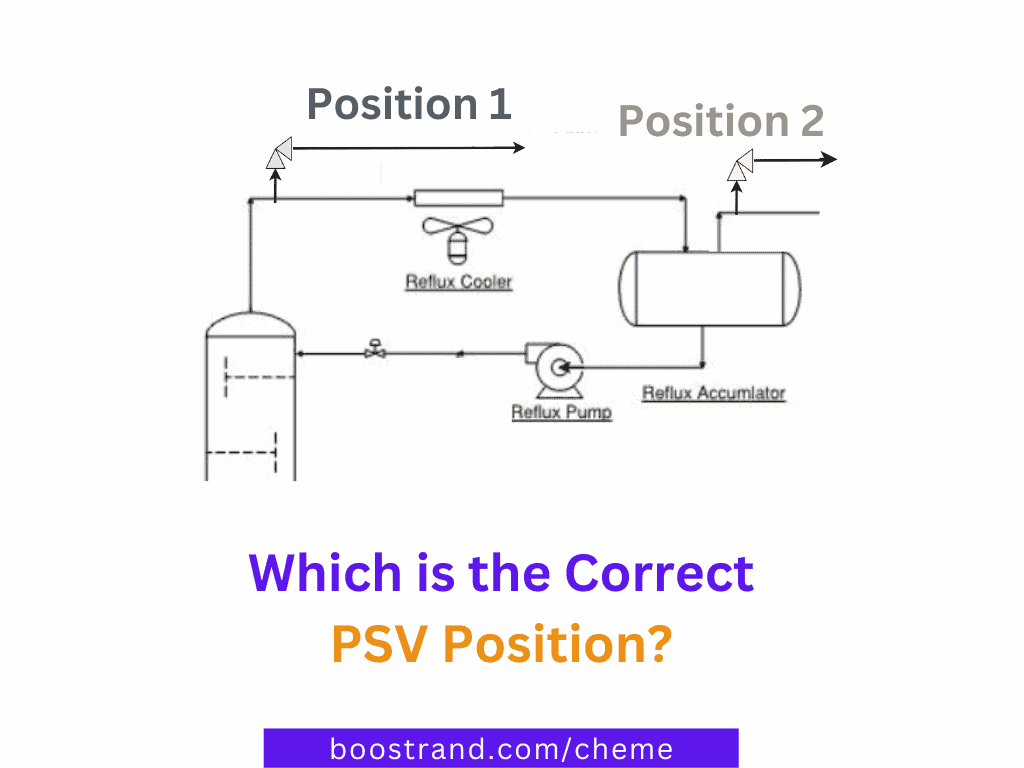

Pressure Safety Valves (PSVs) are the final line of defense against catastrophic overpressure events. While a PSV’s function—opening to release pressure—seems straightforward, sizing these valves requires accounting for numerous complex variables. That’s why we find dedicated references and standards such as API 520 addressing the basic factors when sizing a pressure safety valve. In our article Pressure […]

As process engineers, we design equipment, piping, and other plant components to operate within the conditions that achieve the best operational efficiency and yield on-spec products. However, no one can guarantee that the plant shall always operate within the specified operating envelope. This is because any plant is still subject to lots of disturbances. Disruptions […]

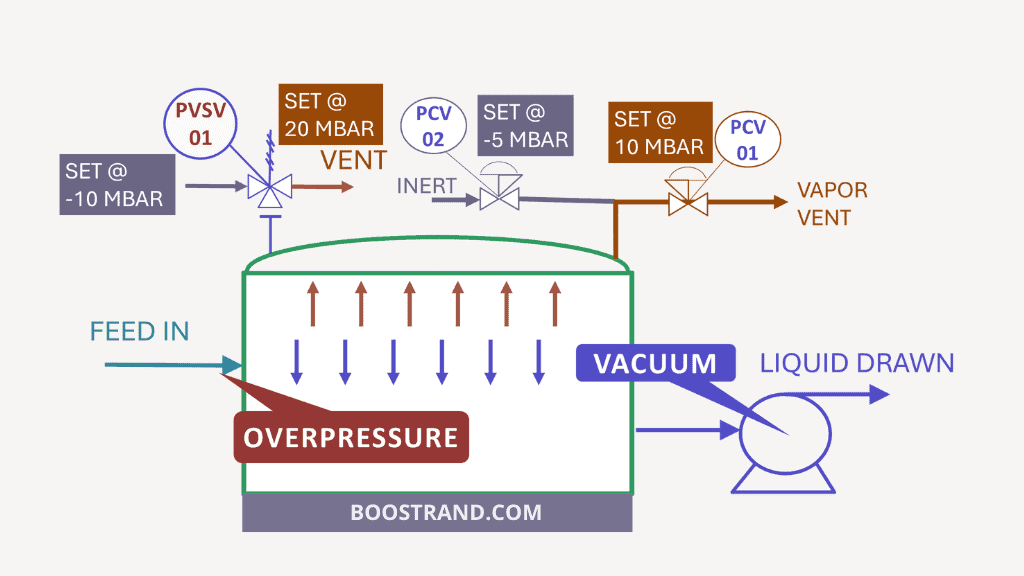

Introduction Proper venting of atmospheric and low-pressure storage tanks is critical to prevent tank damage or failure that could lead to safety and environmental incidents. API Standard 2000, “Venting Atmospheric and Low-pressure Storage Tanks”, is the industry consensus standard that provides requirements and guidance on properly designing normal and emergency tank venting systems. The standard […]

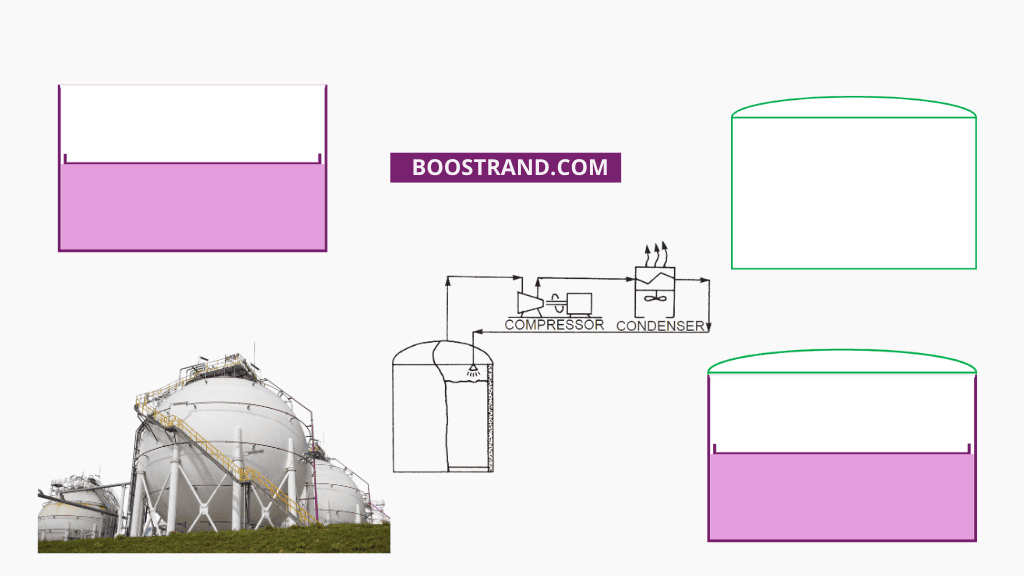

When storage tanks are mentioned, most people think about typical fixed storage tanks. However, things are not that simple. The selection of a storage tank type is a critical process that involves careful consideration of various factors to ensure safe, efficient, and cost-effective storage of fluids. Several key factors influence tank selection, such as fluid […]

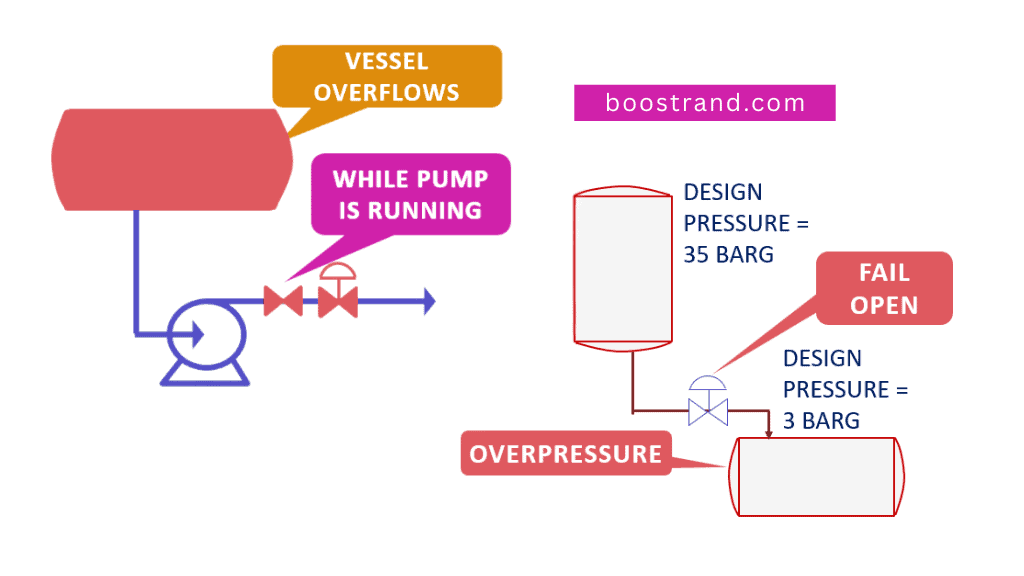

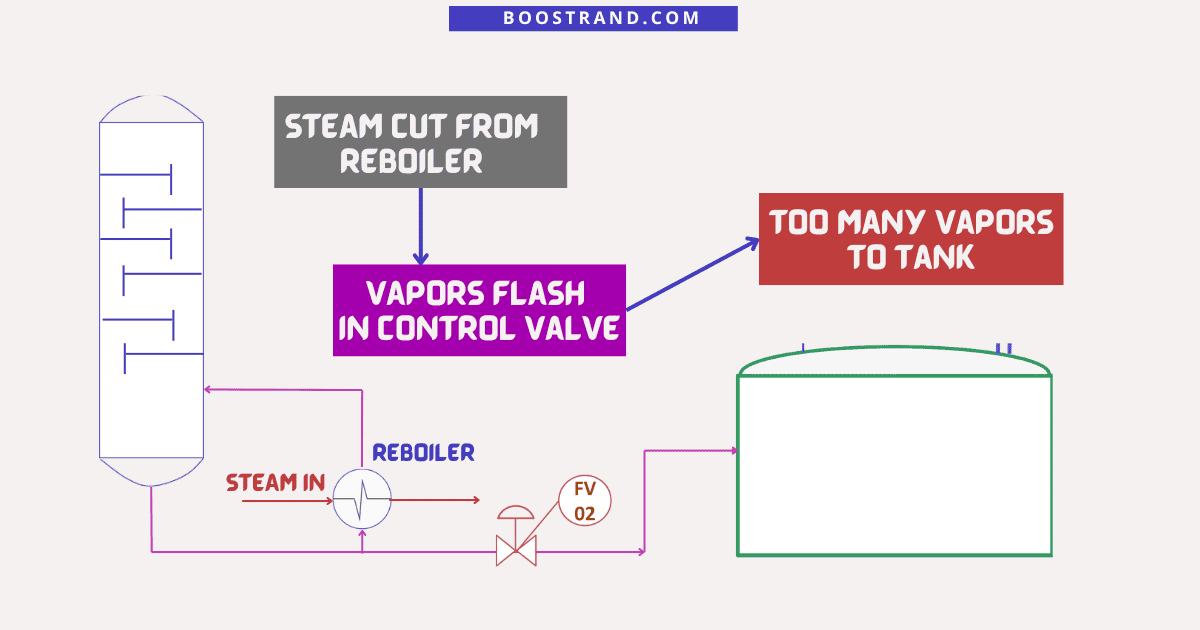

Analyzing upset scenarios is one of the main tasks for process engineers when setting up proper equipment protection. This is clearly shown when preparing the P&IDs, calculating relief loads on the pressure safety valve (PSV) or to the flare system, or carrying out HAZOP / SIL assessment on the current design. Here, a process engineer […]

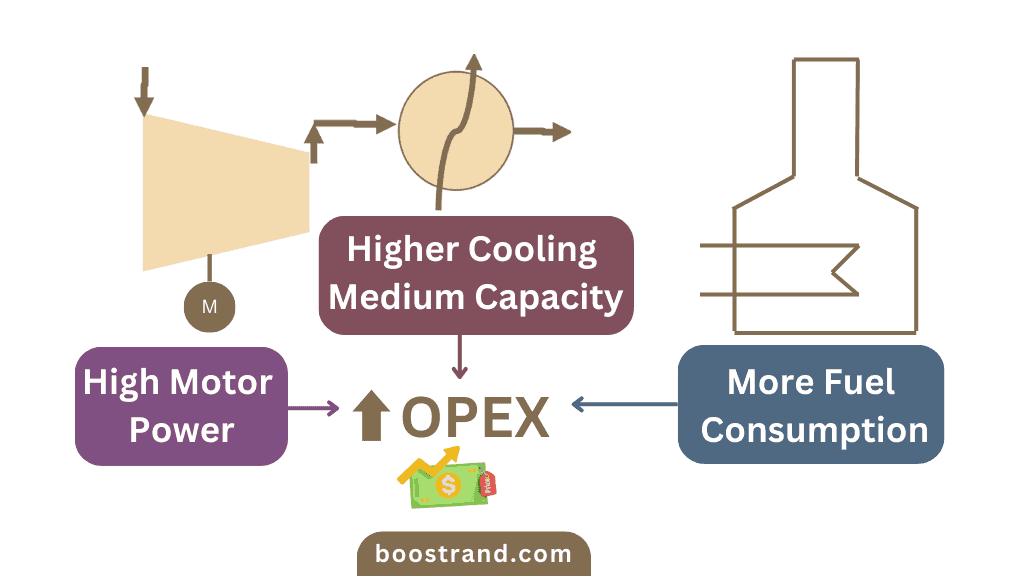

Introduction Energy conservation has become a global trend and a concern for industries worldwide. As energy costs continue to rise and environmental regulations become more stringent, process engineers play a crucial role in designing energy-efficient plants that minimize energy consumption and reduce operating costs. This can be shown in different forms when carrying out the […]

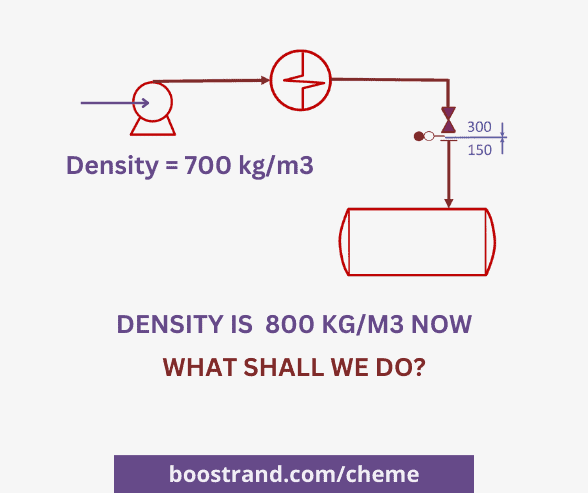

Introduction Pumps are an essential component of many industrial processes. They are used to transfer fluids from one location to another, and their performance is critical to the efficiency and safety of the process. When the operating conditions of a pump change, it can have a significant impact on the pump’s performance. In this article, […]

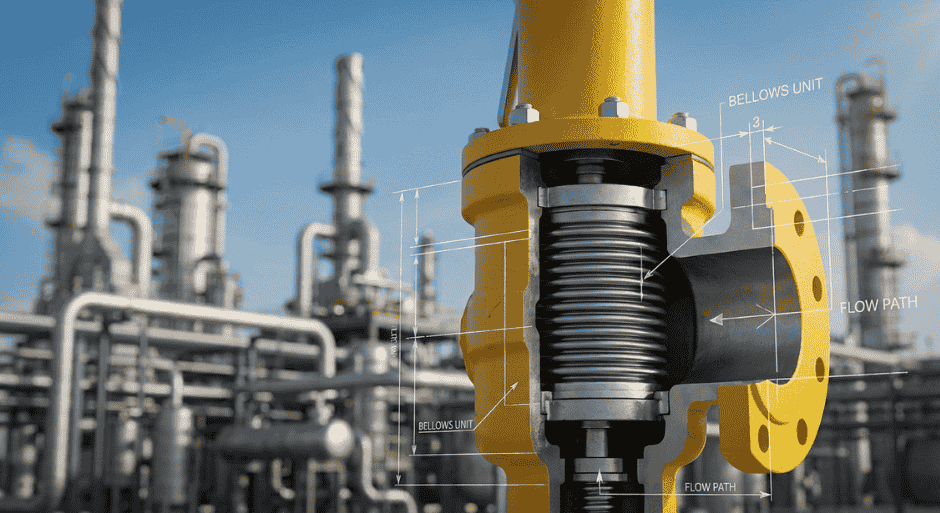

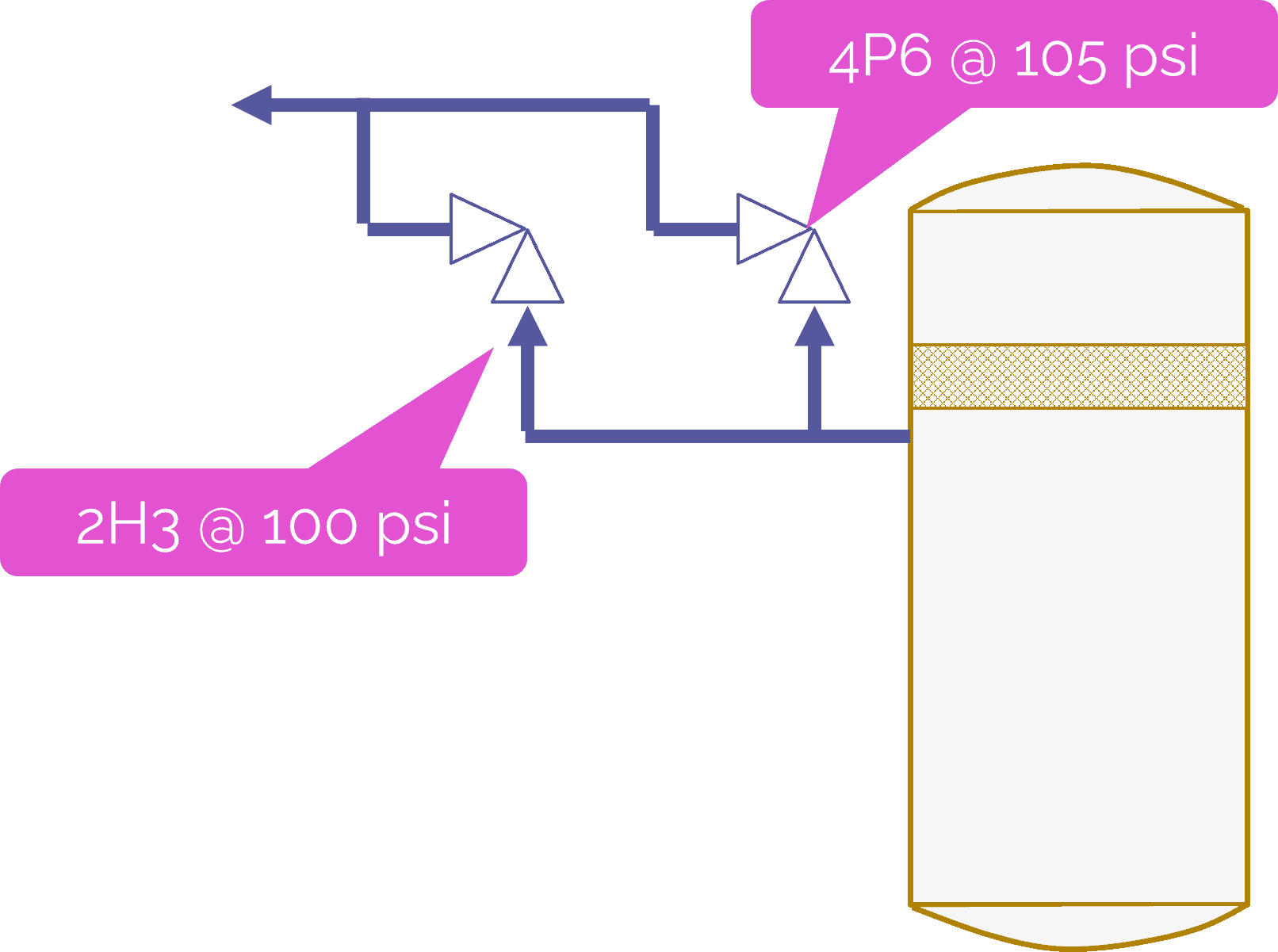

Ensuring the proper protection of a chemical or oil and gas plant from overpressure is one of the major jobs of a process engineer. This is done by analyzing overpressure scenarios and applying different layers of protection. A pressure safety valve (PSV) is on these protection layers. Designed to release excess pressure within a system, […]

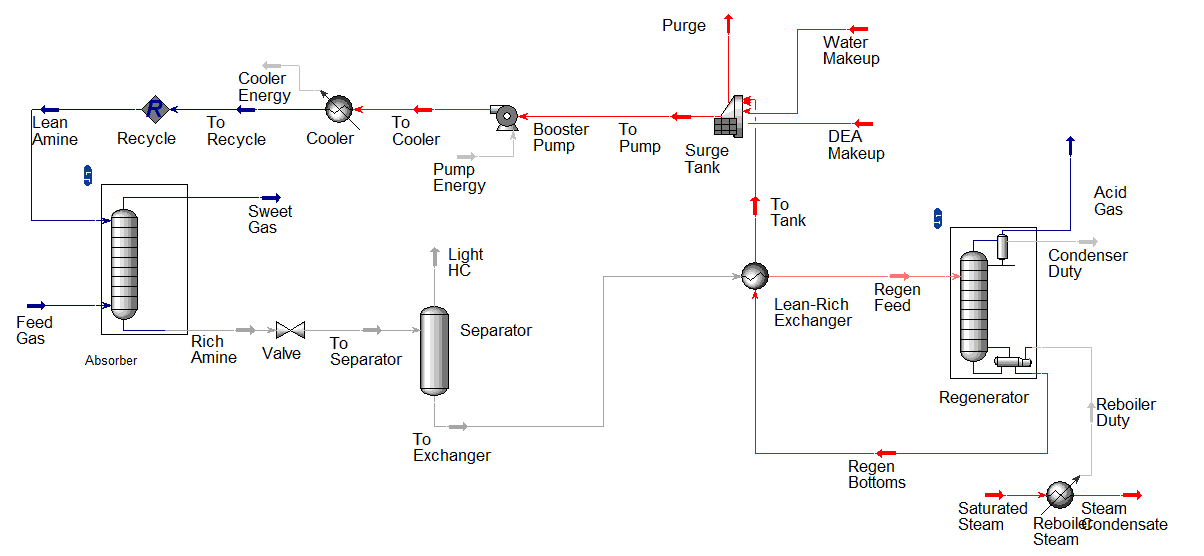

Transforming natural gas into a product that meets commercial standards and safety requirements involves removing various impurities. The first impurity that is commonly removed is related to acid gases. Acid gases are mainly carbon dioxide (CO2), and hydrogen sulfide (H2S). This process of removing acid gases from natural gas is called gas sweetening. The most […]

As we discussed in a previous article, Pressure Safety Valves (PSVs) play a crucial role in maintaining safe operations in chemical process engineering by protecting equipment from overpressure conditions. Due to their high importance and criticality, we should have a clear understanding of the parameters that highly affect the PSV operation and minimize their issues […]