This course offers a practical and theory-backed approach to separator design and sizing, guiding learners through key concepts such as droplet size, K factor, residence time, and operating conditions like foaming and slugging. Through lectures, case studies, and Excel-based exercises, you’ll learn to select appropriate separator types and internals, apply separation criteria, and design both two-phase and three-phase vessels tailored to real-world process requirements.

What’s inside this course

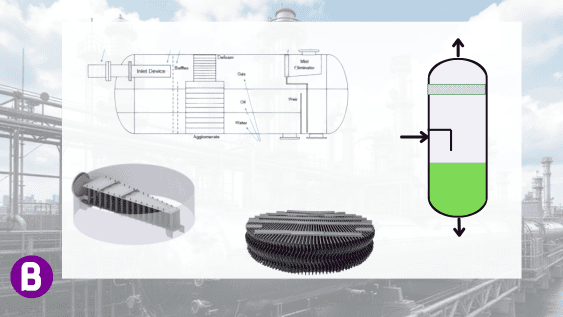

- Basic theory of liquid-liquid or gas-liquid separation

- Major Separation Parameters and how they reflect in separation efficiency

- Understand how a vessel acts as a surge drum and the surge time criteria

- Select the proper Vessel Configuration and Internals based on the required purpose

- Detailed Vessel Sizing Criteria and Common Practices

- Organized Procedure for Vessel Sizing

- Detailed Examples for Sizing Different Vessel Configurations using Excel sheets

- How Vessel Sizing is Integrated in a Project

Need a full Process Engineering Course from Zero to Hero?