Pressure Safety Valves (PSVs) are the final line of defense against catastrophic overpressure events. While a PSV’s function—opening to release pressure—seems straightforward, sizing these valves requires accounting for numerous complex variables. That’s why we find dedicated references and standards such as API 520 addressing the basic factors when sizing a pressure safety valve.

In our article Pressure Safety Valves: An Essential Protection Against Overpressure, we talked about the main functions of a PSV, expected relief scenarios and sizing procedure. However, we shall focus in this article on one of these factors, which is the Backpressure Correction Factor, denoted as Kb.

If you are a process engineer who is sizing a PSV, understanding Kb is essential. This is because it can dramatically impact your PSV sizing. In this article, you’ll learn:

- How to determine Kb values using API 520 charts

- What the backpressure correction factor (Kb) is and why it matters

- How Kb affects PSV orifice area calculations

- When to apply Kb based on valve type and flow conditions

The Context: What is Backpressure?

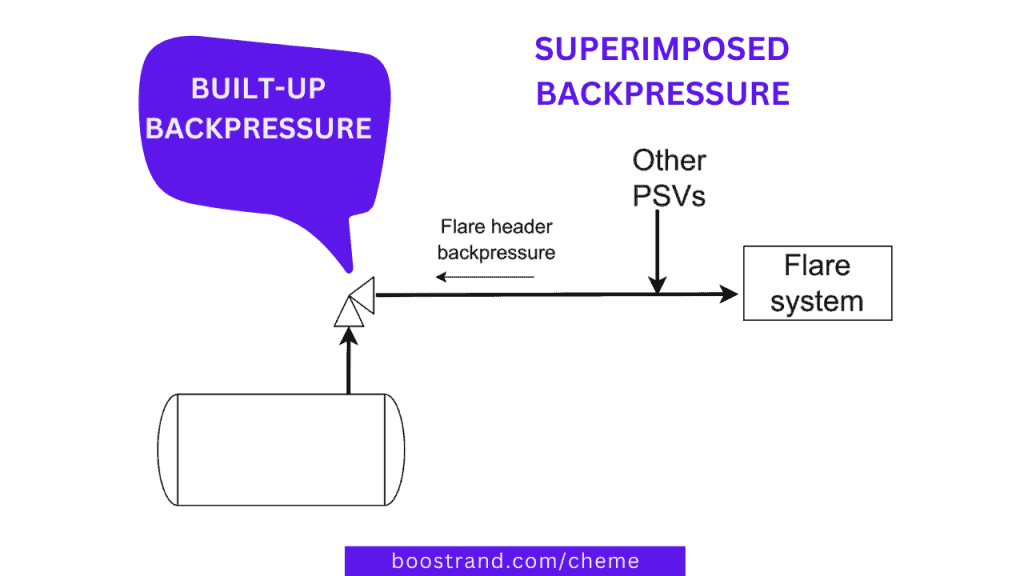

Before we define the factor, we must understand the effect it represents. When a PSV opens, it discharges fluid into a header system or a tailpipe that leads to a flare or a safe location. The pressure existing at the outlet of the PSV is known as backpressure.

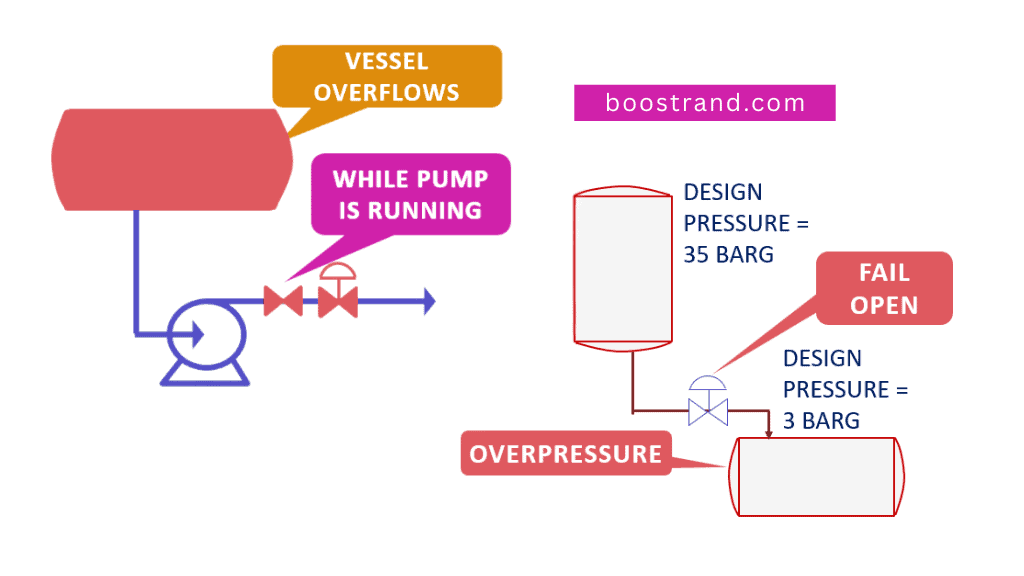

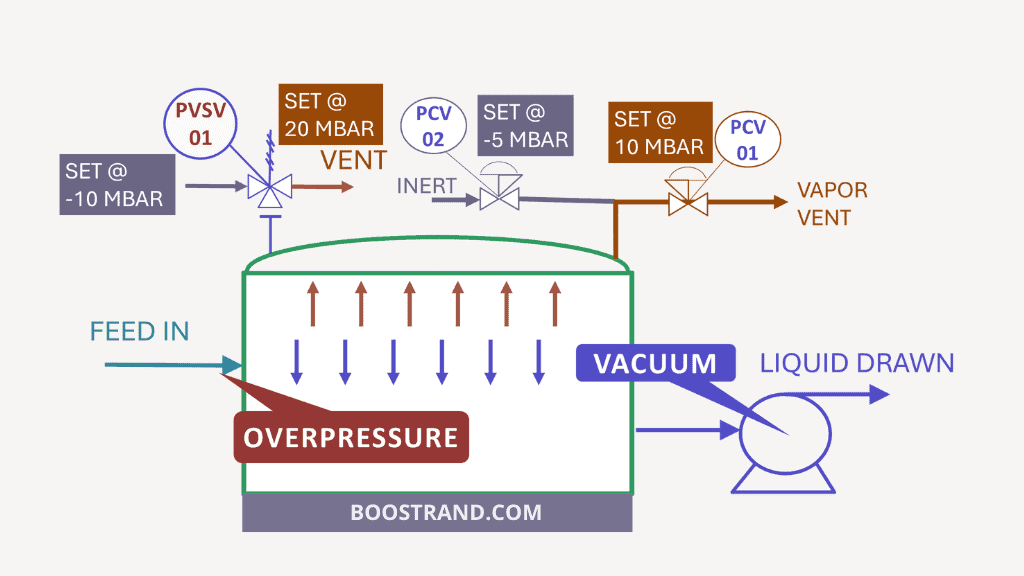

As detailed in our overview of pressure safety valves, backpressure comes in two forms:

- Superimposed Backpressure: The pressure already present in the discharge header before the specific PSV opens.

- Built-up Backpressure: The pressure generated inside the discharge pipe because the PSV is flowing.

High backpressure can hinder the lifting force of the valve disc or reduce the capacity of the valve. This is where the correction factor (Kb) comes into play.

What is Kb?

The Backpressure Correction Factor (Kb) is a multiplier used in the API 520 sizing equations to account for the reduction in flow capacity caused by backpressure. Essentially, as backpressure increases, the efficiency of the valve may decrease. The Kb factor “derates” the valve’s theoretical capacity to reflect reality.

Why does this matter? Let’s look at the math. The below equation is used as per API 520 to calculate the required orifice area of a PSV:

- A = Required discharge area

- W = Required mass flow rate

- Kb = Backpressure correction factor

As we see, in order to calculate the required discharge area (A), we need to know the correction factors in the denominator. Here we are concerned with Kb, which is the backpressure factor.

Because Kb is in the denominator, a value lower than 1.0 results in a larger required orifice area. Here’s why this matters:

Example:

Imagine you have a balanced bellows valve with high backpressure, resulting in a Kb of 0.80.

If you incorrectly assumed Kb = 1.0, your calculated area would be 20% smaller than what is actually required. This could lead to selecting an undersized valve. An undersized valve cannot evacuate the fluid fast enough, leading to vessel overpressure and potential failure.

However, Kb is not applied universally to every valve. Its application depends entirely on the type of PSV you have selected. Also the type of flow whether it’s critical or subcritical shall affect the value of Kb. So let’s go through these factors.

PSV and Relief System Sizing

Learn PSV sizing for different scenarios, understand depressurization, blowdown & flare system components, and analysis.

Factors Affecting Kb Calculation

Critical vs subcritical Flow

For gas or vapor relief, we must determine whether the flow is choked (critical) or subcritical.

- Critical Flow: This will happen if there is a large difference between backpressure and inlet pressure. In this case, the gas exit velocity from the PSV nozzle reaches a maximum velocity (sonic velocity) that it cannot exceed. In addition, the outlet pressure at the nozzle doesn’t fall below the critical pressure even if the backpressure is much less. This would lead to a choked flow. This is the most common case.

- Subcritical Flow: In rare cases where backpressure is so high that flow becomes subcritical, This would require a different equation than the above one (refer to API 520 Section 5.6.4).

PSV Type

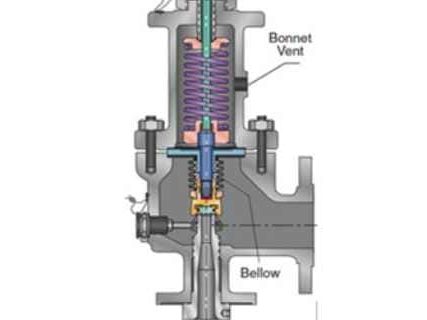

Conventional and Pilot-Operated Valves

- Conventional Valves: These are generally used when backpressure is very low (typically less than 10% of the set pressure). If backpressure is high, we don’t usually adjust Kb; instead, we switch to a different valve type because high backpressure changes the set pressure of a conventional valve, making it unreliable.

- Pilot-Operated Valves: These are robust against backpressure. The pilot mechanism ensures the main valve lifts fully even against high backpressure, so the capacity is generally not derated.

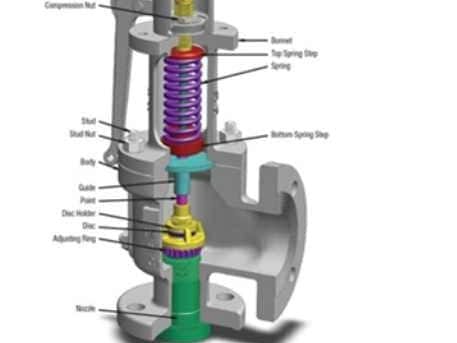

Balanced Bellows Valves

The Kb factor is applied specifically to Balanced Bellows Valves.

Balanced bellows valves are designed with a mechanical bellows that shields the top of the disc from backpressure. This ensures the valve opens at the correct set pressure even if the backpressure is high or variable. However, the physical presence of the bellows and the flow dynamics at high backpressure can reduce the actual flow capacity. The Kb factor corrects for this capacity loss.

Determining the Value of Kb

So based on the above, how shall we determine Kb factor?

Conventional or Pilot-Operated Valve at Critical Flow

Kb shall be taken as 1.

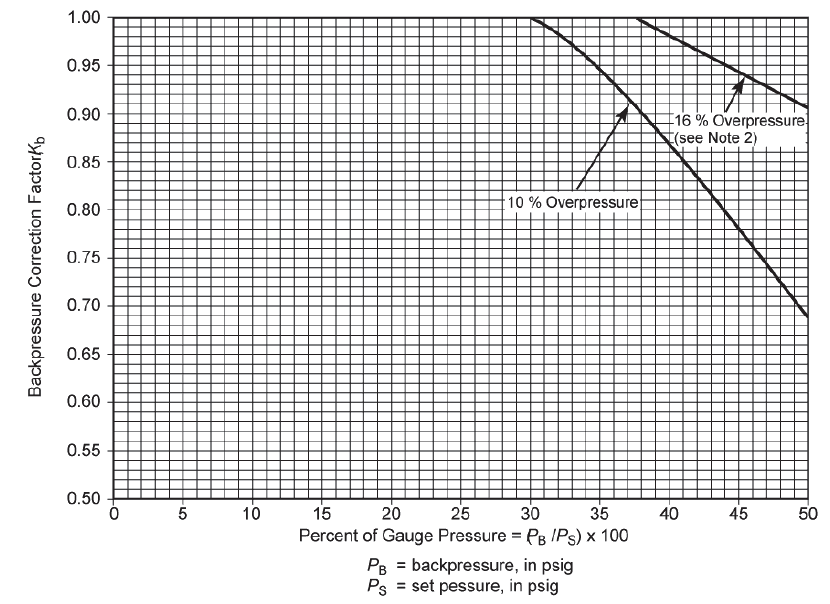

Balanced Bellows valve at Critical Flow

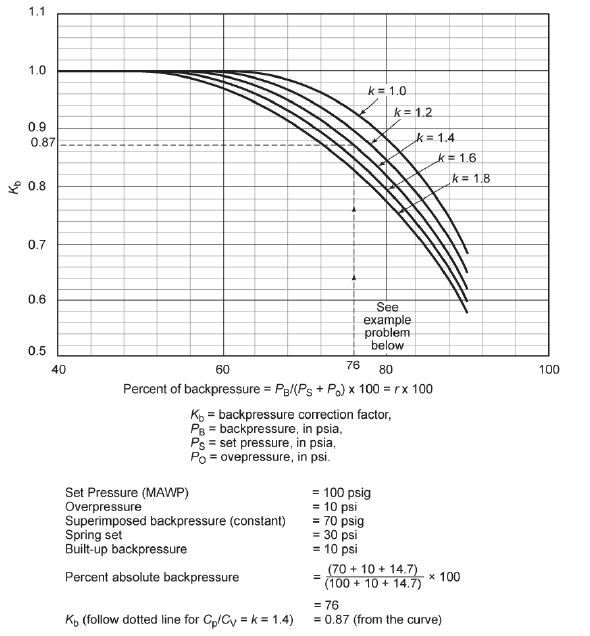

For preliminary sizing of vapor service, you can estimate Kb using the below chart in API 520. These charts plot the backpressure percentage against the Kb factor. You will notice that as backpressure increases, Kb drops significantly below 1.0.

So here we see that Kb factor starts to decrease when backpressure exceeds 30-40%, depending on overpressure. The chart is limited to a 50% backpressure as is the maximum limit for selection of Balanced Bellows Valve.

N.B. If you’d like to understand the concept of PSV overpressure and other PSV operational concepts, you can check out our article 4 Key Factors Affecting PSV Sizing & Operation.

Conventional or Pilot-Operated Valve at Subcritical Flow

As highlighted above, the PSV orifice area is calculated using a different equation for subcritical flow. However, API 520 suggests an alternative way to use the above equation. In addition, it provides the below chart to get the value of Kb for conventional or pilot-operated PSVs. This chart doesn’t apply to Balanced Bellows PSV.

Balanced Bellows valve at Subcritical Flow

The calculation of Kb is the same as the balanced bellows valve for critical flow. However, this needs confirmation from the PSV manufacturer.

Note: Always remember that while API charts are excellent for preliminary sizing, the final Kb should be obtained from the specific valve manufacturer’s literature once a vendor is selected.

Conclusion

As process engineers carrying out the PSV sizing, we must look beyond just the “Set Pressure.” We must understand the hydraulic conditions of the entire relief system. The Backpressure Correction Factor Kb is a vital component in ensuring that Balanced Bellows valves are sized conservatively and correctly.

By applying Kb correctly, you ensure that the PSV can relieve the required flow even when the flare header is pressurized.

Start your Career

Access Process Engineering Introduction Course

Share this:

[…] creation of a PFD is typically based on the output of process simulation software. We have discussed plant simulation’s role in a project in the previous article. In a nutshell, process simulation involves using specialized software to model and analyze the […]