Articles

As process engineers, we design equipment, piping, and other plant components to operate within the conditions that achieve the best operational efficiency and yield on-spec products. However, no one can guarantee that the plant shall always operate within the specified operating envelope. This is because any plant is still subject to lots of disturbances. Disruptions […]

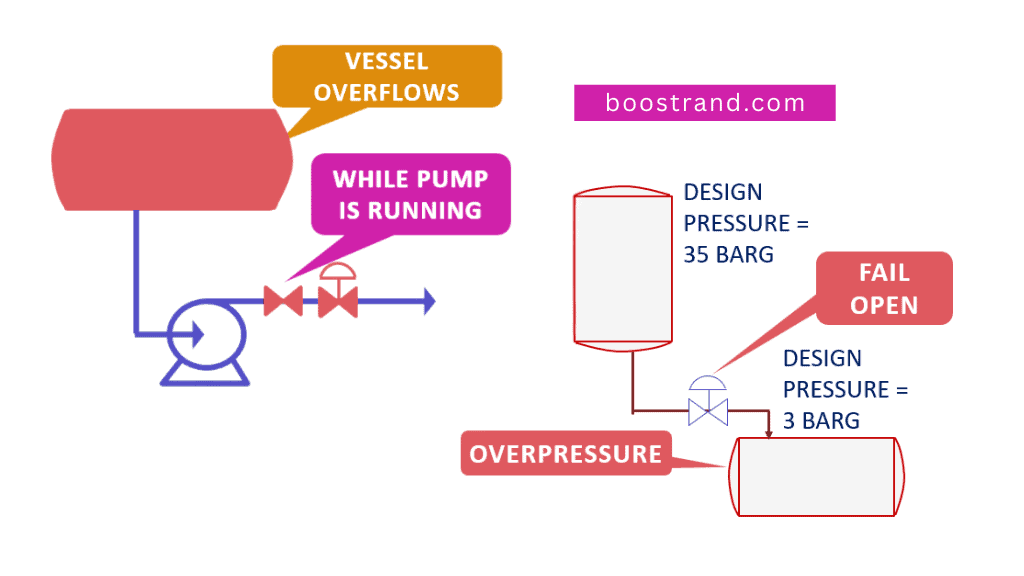

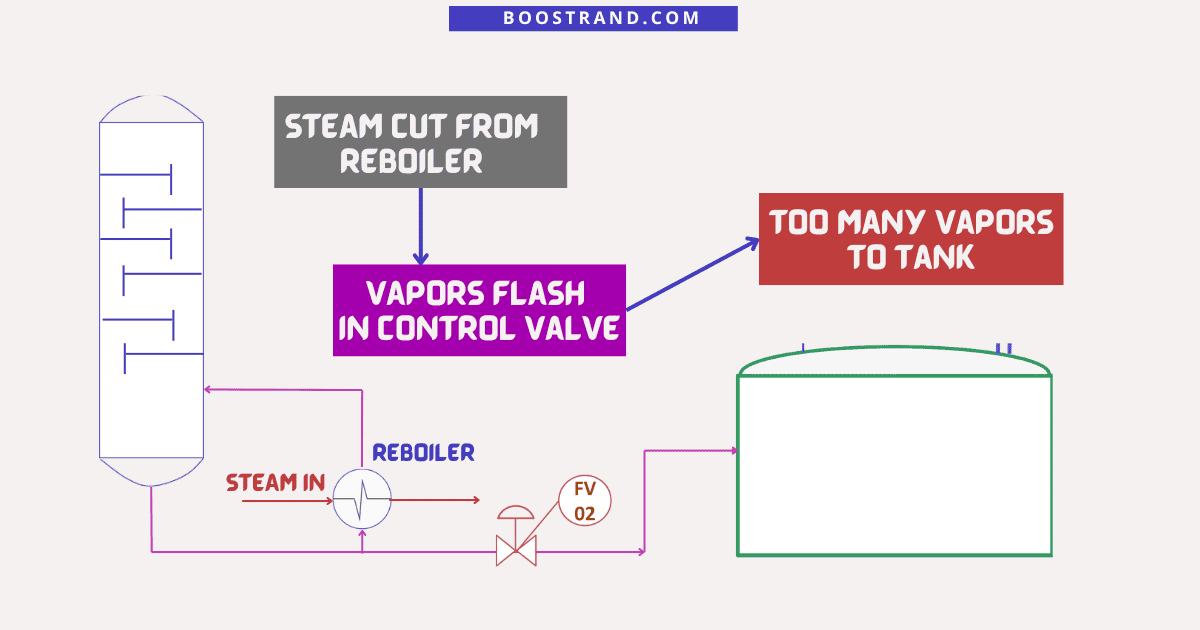

Analyzing upset scenarios is one of the main tasks for process engineers when setting up proper equipment protection. This is clearly shown when preparing the P&IDs, calculating relief loads on the pressure safety valve (PSV) or to the flare system, or carrying out HAZOP / SIL assessment on the current design. Here, a process engineer […]

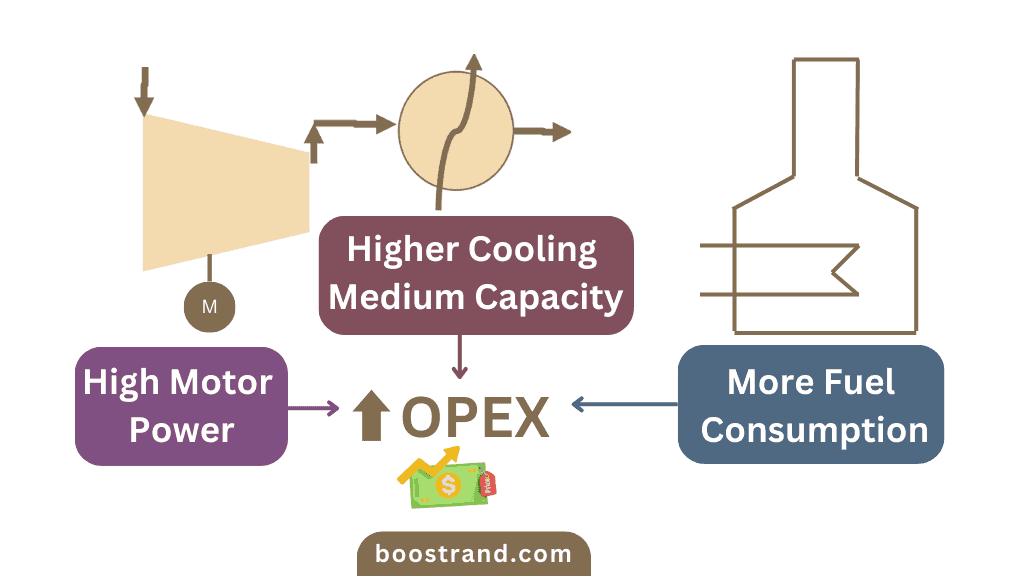

Introduction Energy conservation has become a global trend and a concern for industries worldwide. As energy costs continue to rise and environmental regulations become more stringent, process engineers play a crucial role in designing energy-efficient plants that minimize energy consumption and reduce operating costs. This can be shown in different forms when carrying out the […]

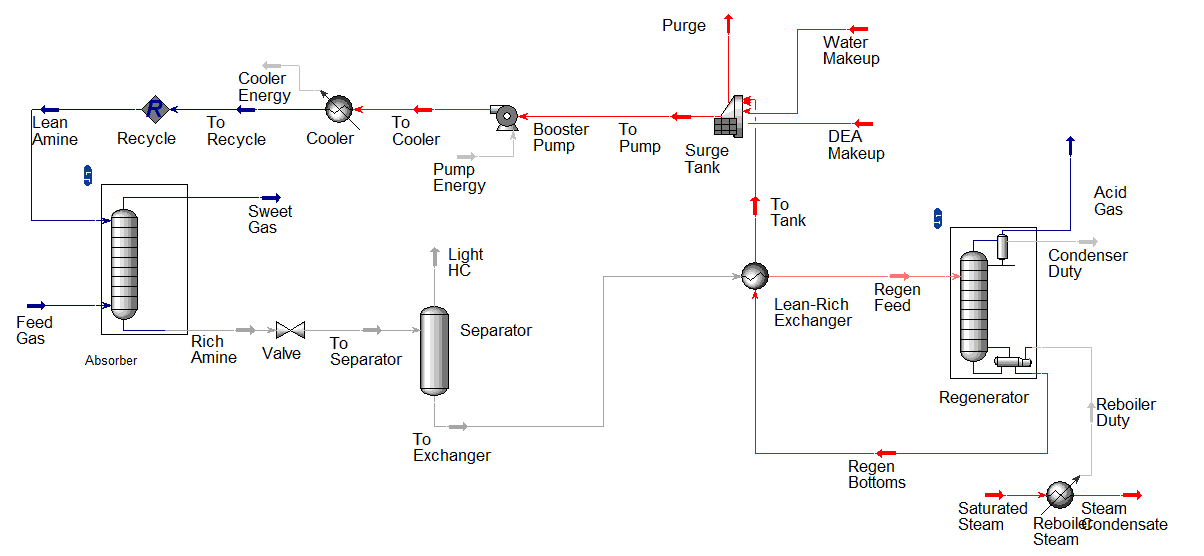

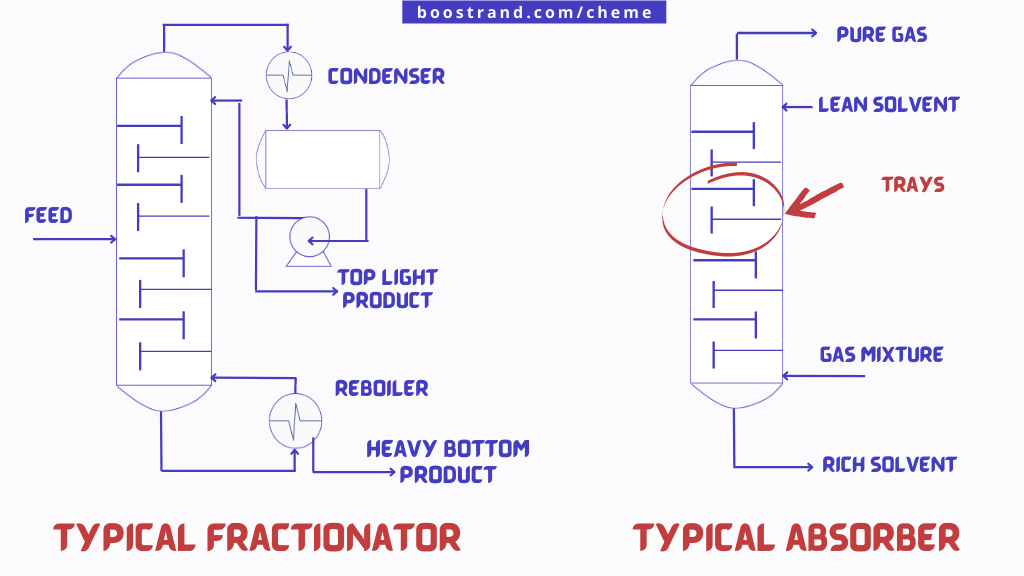

Transforming natural gas into a product that meets commercial standards and safety requirements involves removing various impurities. The first impurity that is commonly removed is related to acid gases. Acid gases are mainly carbon dioxide (CO2), and hydrogen sulfide (H2S). This process of removing acid gases from natural gas is called gas sweetening. The most […]

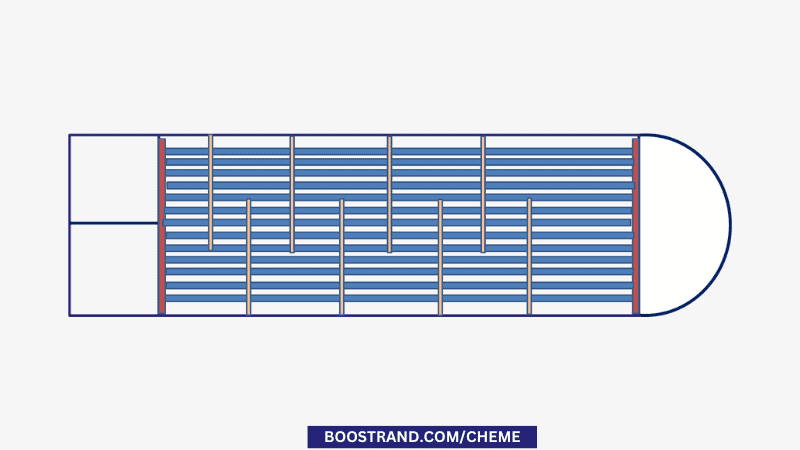

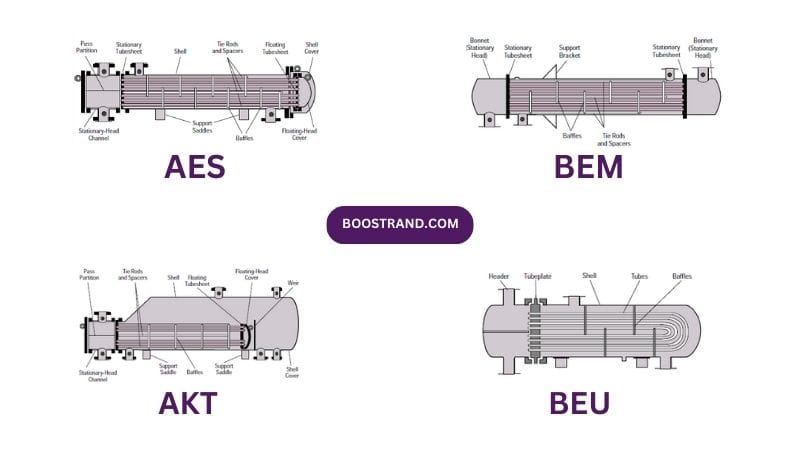

Shell and tube heat exchangers are the backbone of many industries, offering a versatile solution for heat transfer processes. If you went through any refinery or gas plant or chemical or petrochemical plants, you must have seen plenty of shell and tube exchangers. In this article, we shall go through the core aspects of optimizing […]

Introduction Choosing the right heat exchanger for your specific service is a critical decision that can significantly impact the efficiency and cost-effectiveness, operation, and maintenance of your shell and tube heat exchanger. That’s why selecting the optimum Exchanger TEMA (Tubular Exchanger Manufacturers Association) type is crucial to ensure optimal performance and easy maintenance. In this […]

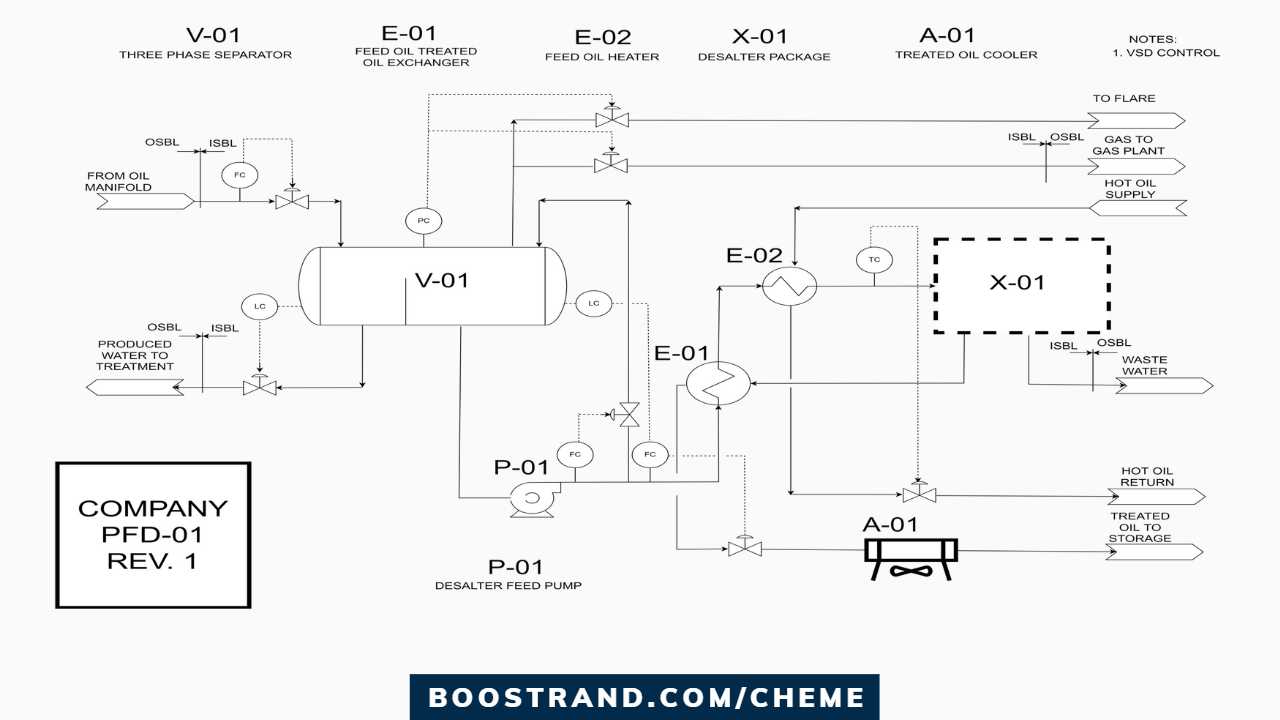

So we started our project, we carried out our plant simulation activities, and we modeled different cases using simulation software. Now, it’s time to wrap up all that we have modeled. This is an essential step in order to move forward in the project. Here comes the role of a Process Flow Diagram (PFD). A […]

Process engineering plays a pivotal role in industries such as chemical, oil and gas, petrochemical, and pharmaceuticals. It encompasses designing and optimizing processes that convert raw materials into valuable products. As the backbone of a project, process engineers collaborate closely with various disciplines, including piping, instrumentation, and mechanical engineering. Their primary objective is to ensure […]

Process design plays a crucial role in the success of any plant operation. It’s a long journey starting from process modeling and passing through sizing and design activities, then ensuring that process components are procured as requested up to starting up the plant at site. This involves a series of decisions and calculations, including equipment […]

A process engineer has a great role in any oil and gas, chemical, or petrochemical project. This is because based on the process design he performs, the cost and schedule of the project, operability and safety of the plant shall be determined. In a previous article, we have talked about the process design documents and […]

Process design is the cornerstone of any successful project. That’s because a process engineer plays a crucial role in creating efficient, safe, and sustainable processes. Through a deep understanding of chemical engineering principles, a process engineer can deliver an optimized and sustainable process design. This can be seen from the start of the project when […]

Towers represent a major component in most refining and petrochemical processes. In any major plant, you can see one tower or more. An efficient operation of a tower is a bit complicated and depends on many factors. If you’d like to see the content of this article as a video, you can check out our […]

.png)

Process control is essential in any plant to ensure that the operating parameters are within their acceptable limits. When we open a process flow diagram (PFD), we can see different control loops controlling various equipment in any plant. In all these various industries, process control schemes are considered, whether we are talking about oil and […]

Separation is an essential process that is carried out in any plant, whether it was an oil facility, a gas plant, a refinery or a petrochemical complex, or in any other chemical processing plant. There are many separation methods depending on the fluid physical properties, whether it was the difference in boiling points as in […]

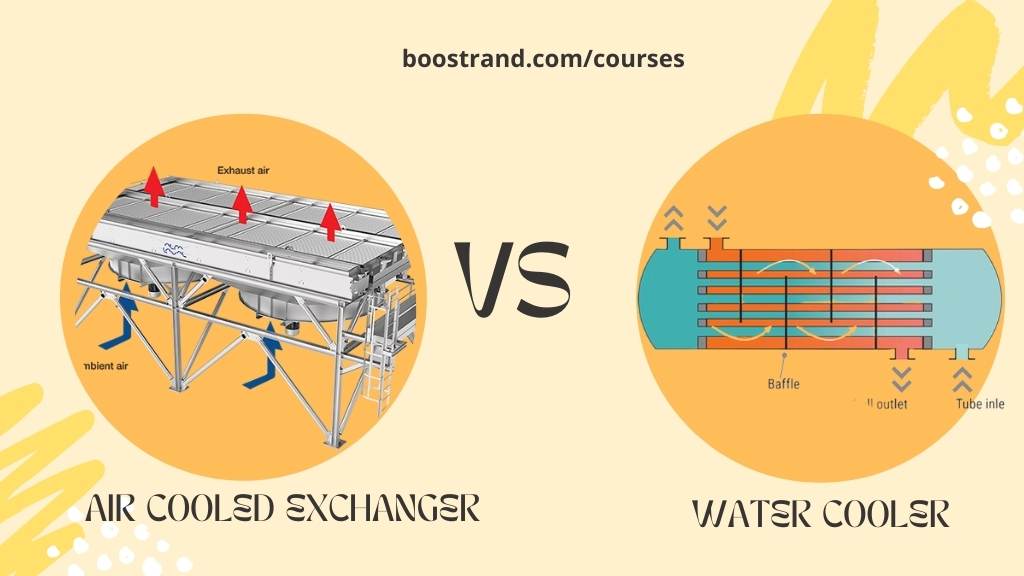

So we have a fluid that we need to be cooled down? Which piece of equipment shall we use? Shall we use a heat exchanger which is in most cases a shell and tube exchanger, cooling with water or another fluid? Or shall we use an air-cooled heat exchanger, cooling with air fans? This depends […]