Subcategories

Case Studies Compressors Control Valves Equipment Protection Heat Exchangers Hydraulics P&ID Design Process Control Process Design Process Simulation PSV Pumps Storage Tanks Towers Vessels

Articles

As process engineers, we design equipment, piping, and other plant components to operate within the conditions that achieve the best operational efficiency and yield on-spec products. However, no one can guarantee that the plant shall always operate within the specified operating envelope. This is because any plant is still subject to lots of disturbances. Disruptions […]

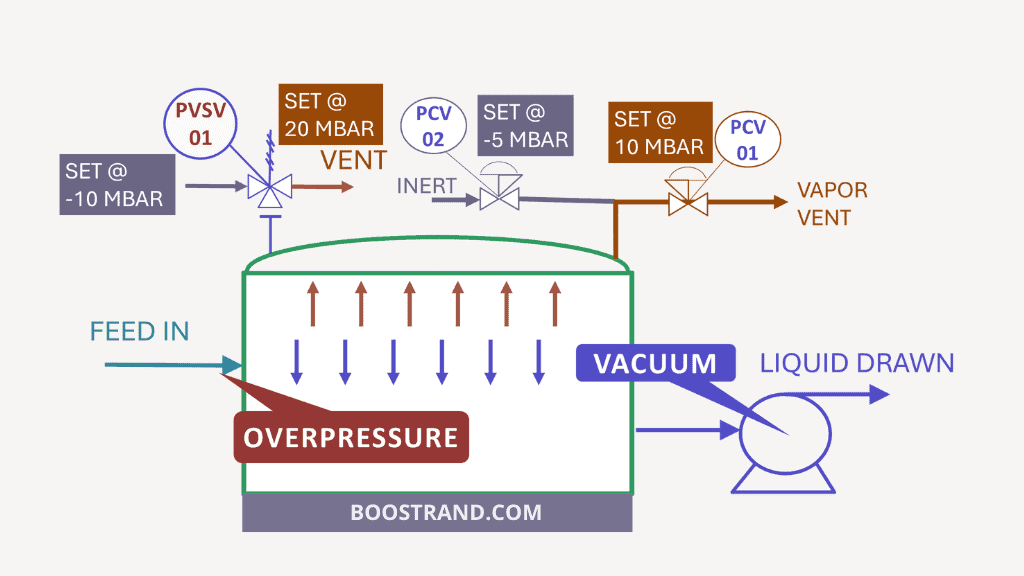

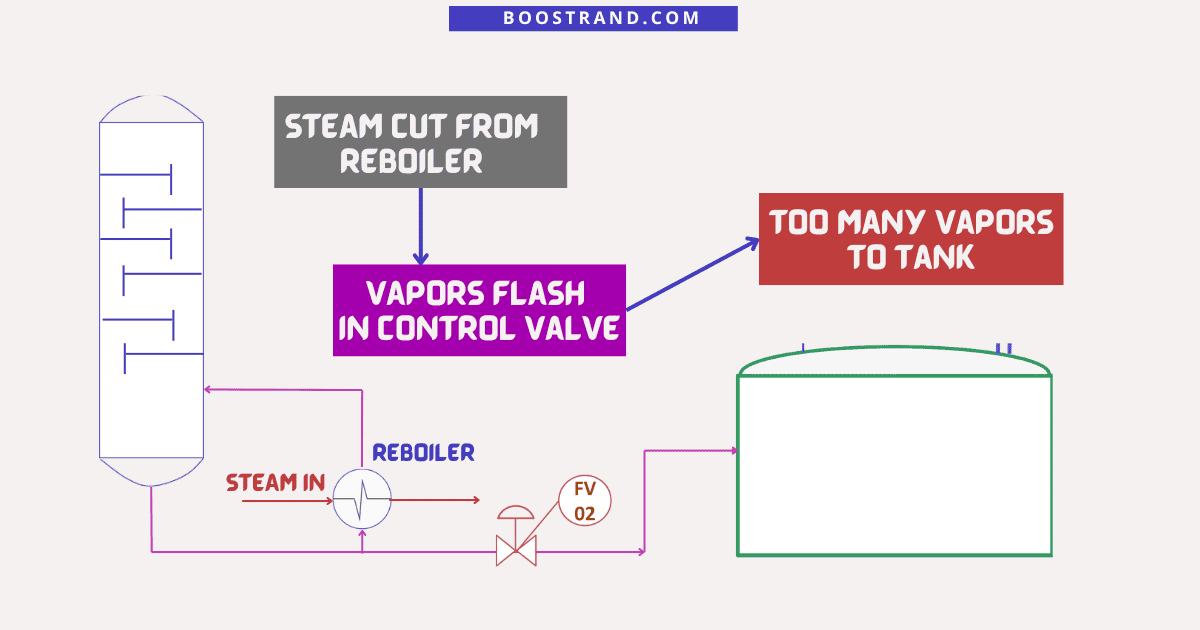

Introduction Proper venting of atmospheric and low-pressure storage tanks is critical to prevent tank damage or failure that could lead to safety and environmental incidents. API Standard 2000, “Venting Atmospheric and Low-pressure Storage Tanks”, is the industry consensus standard that provides requirements and guidance on properly designing normal and emergency tank venting systems. The standard […]

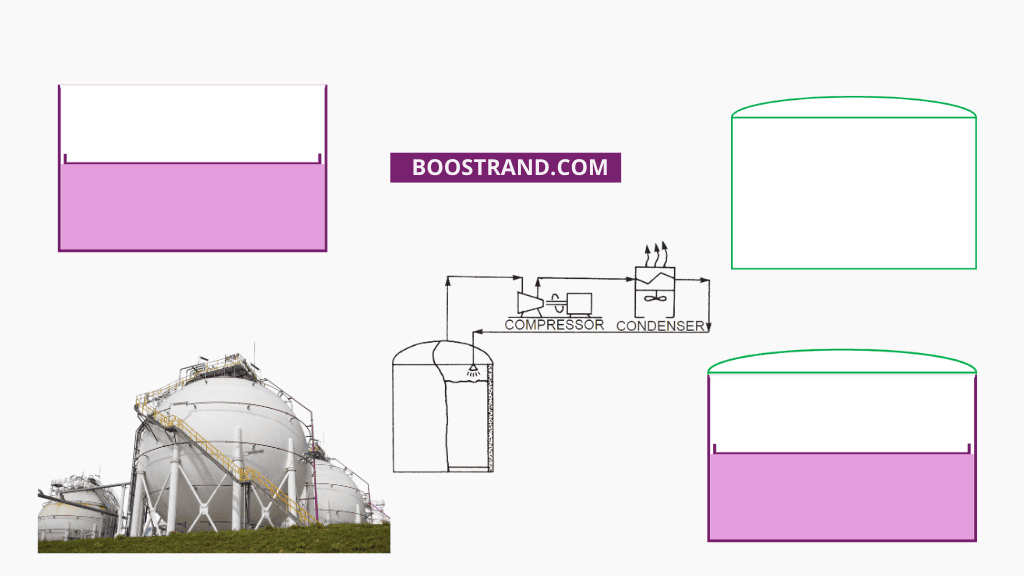

When storage tanks are mentioned, most people think about typical fixed storage tanks. However, things are not that simple. The selection of a storage tank type is a critical process that involves careful consideration of various factors to ensure safe, efficient, and cost-effective storage of fluids. Several key factors influence tank selection, such as fluid […]

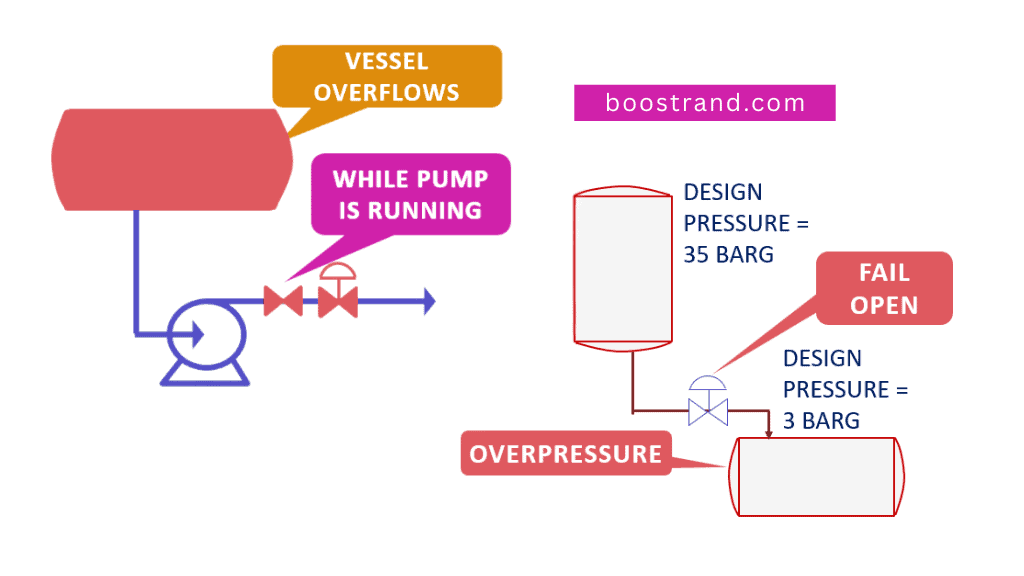

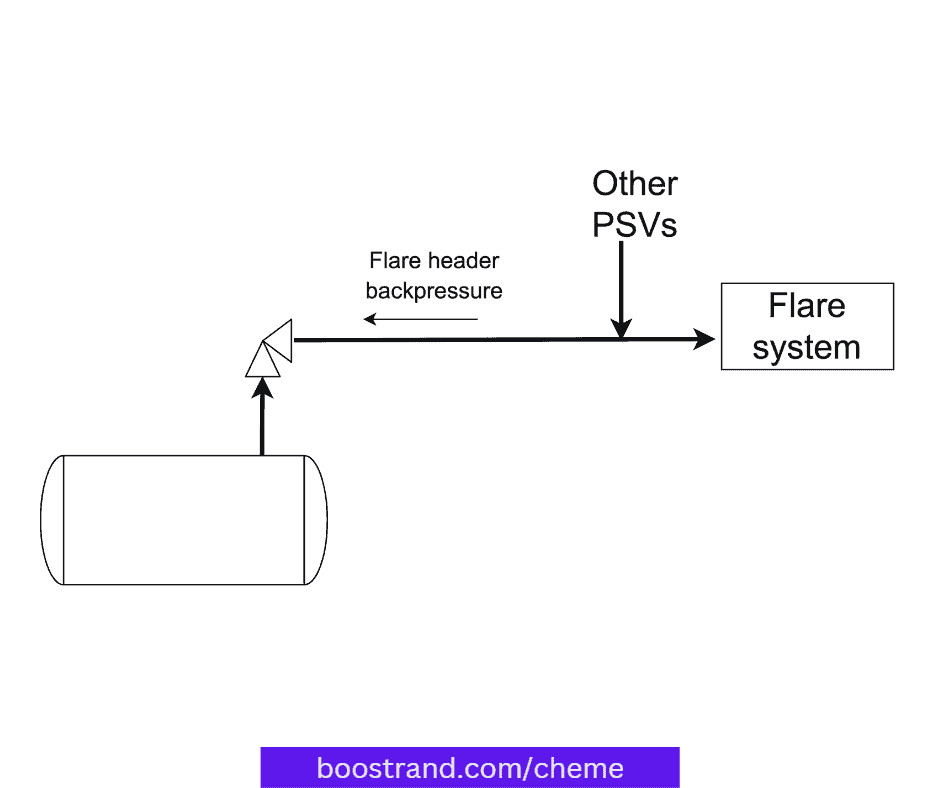

Analyzing upset scenarios is one of the main tasks for process engineers when setting up proper equipment protection. This is clearly shown when preparing the P&IDs, calculating relief loads on the pressure safety valve (PSV) or to the flare system, or carrying out HAZOP / SIL assessment on the current design. Here, a process engineer […]

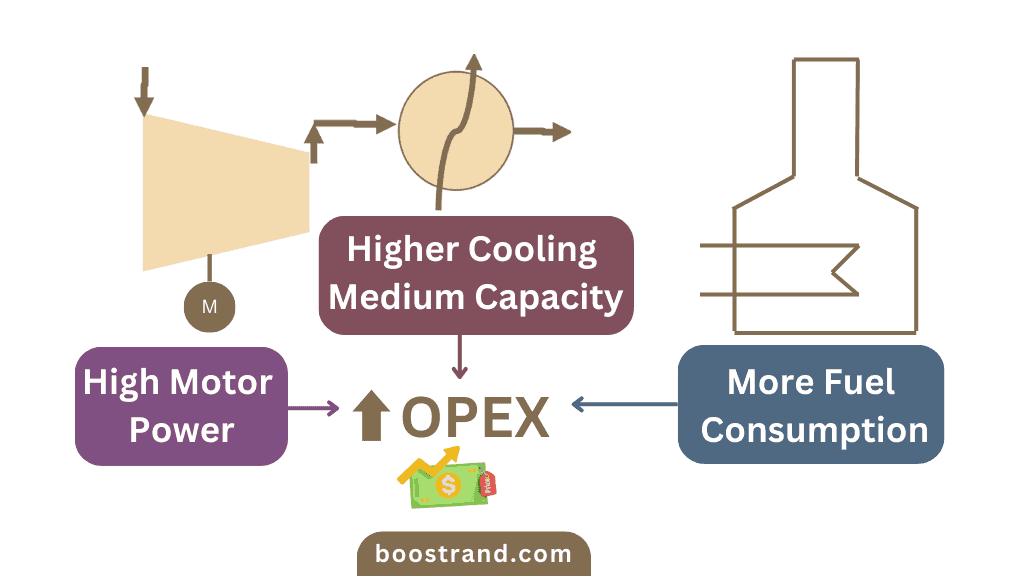

Introduction Energy conservation has become a global trend and a concern for industries worldwide. As energy costs continue to rise and environmental regulations become more stringent, process engineers play a crucial role in designing energy-efficient plants that minimize energy consumption and reduce operating costs. This can be shown in different forms when carrying out the […]

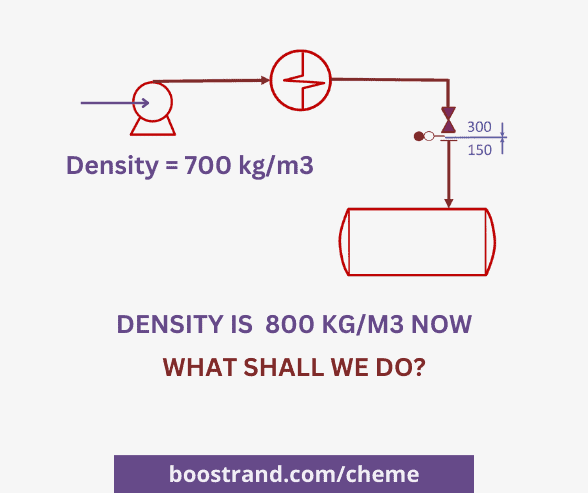

Introduction Pumps are an essential component of many industrial processes. They are used to transfer fluids from one location to another, and their performance is critical to the efficiency and safety of the process. When the operating conditions of a pump change, it can have a significant impact on the pump’s performance. In this article, […]

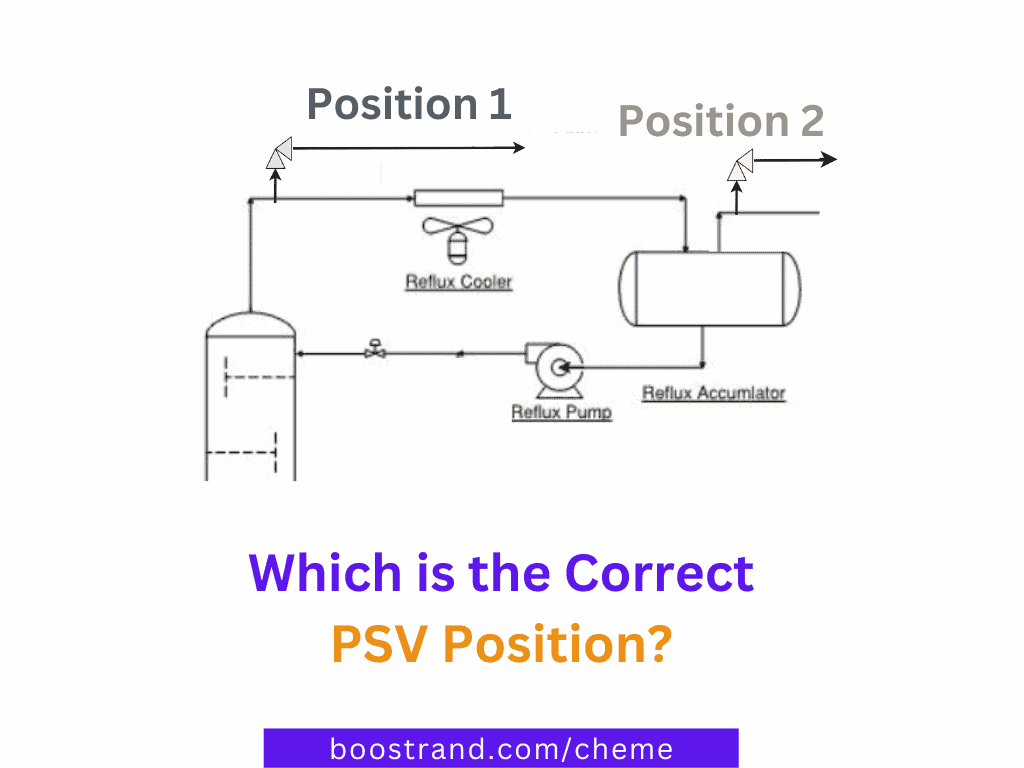

Ensuring the proper protection of a chemical or oil and gas plant from overpressure is one of the major jobs of a process engineer. This is done by analyzing overpressure scenarios and applying different layers of protection. A pressure safety valve (PSV) is on these protection layers. Designed to release excess pressure within a system, […]

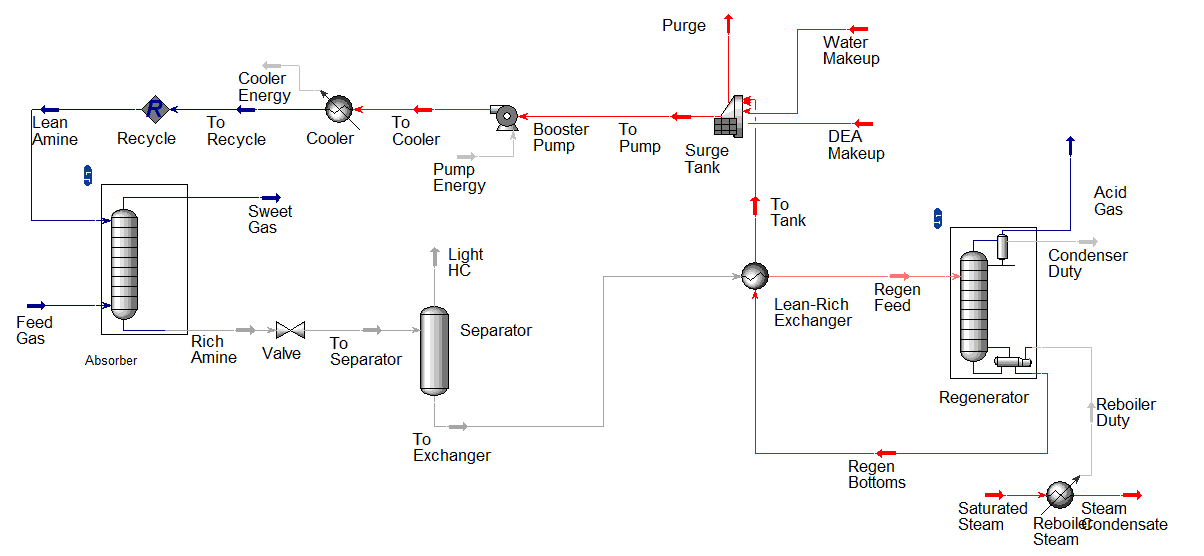

Transforming natural gas into a product that meets commercial standards and safety requirements involves removing various impurities. The first impurity that is commonly removed is related to acid gases. Acid gases are mainly carbon dioxide (CO2), and hydrogen sulfide (H2S). This process of removing acid gases from natural gas is called gas sweetening. The most […]

As we discussed in a previous article, Pressure Safety Valves (PSVs) play a crucial role in maintaining safe operations in chemical process engineering by protecting equipment from overpressure conditions. Due to their high importance and criticality, we should have a clear understanding of the parameters that highly affect the PSV operation and minimize their issues […]

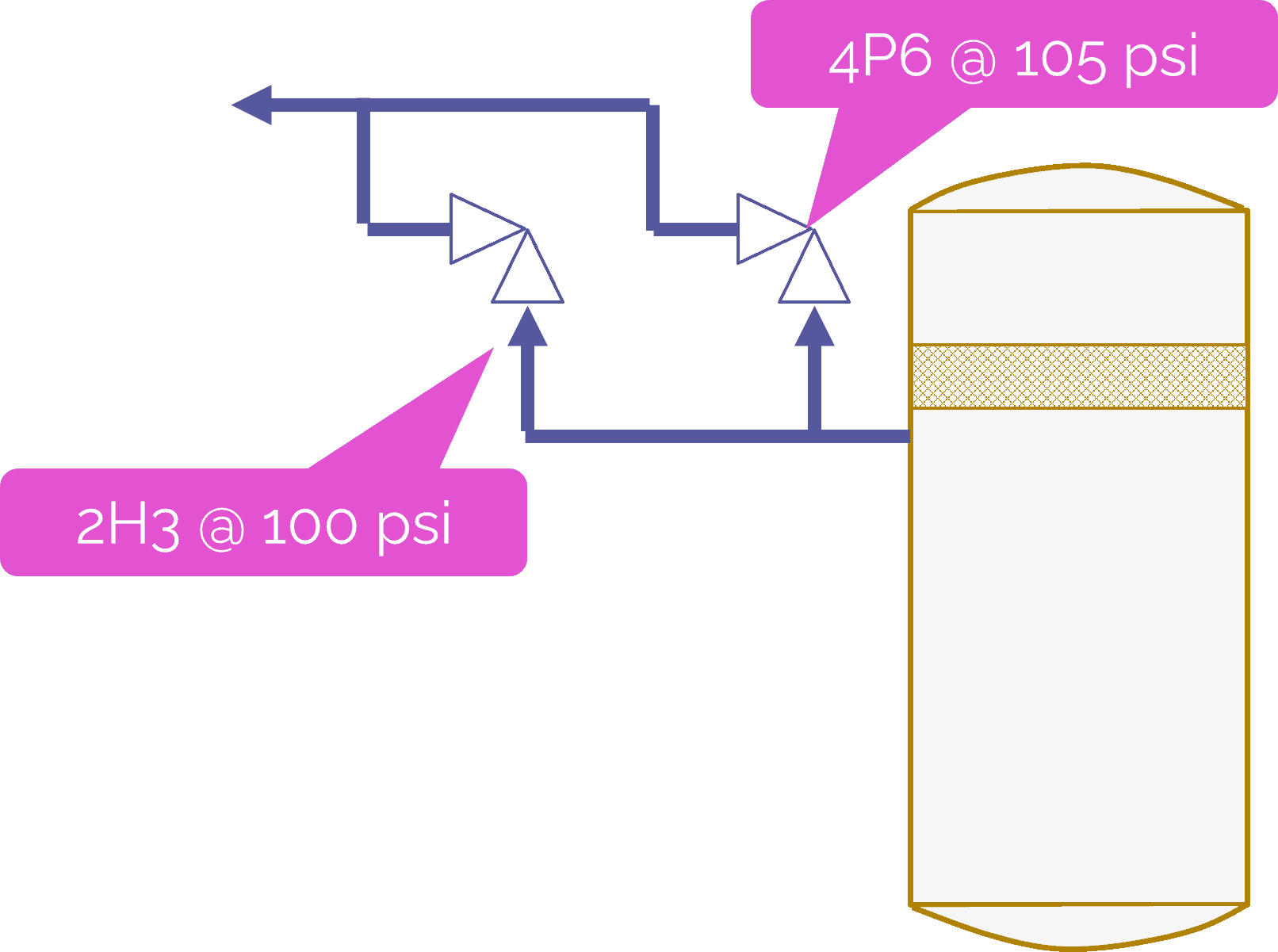

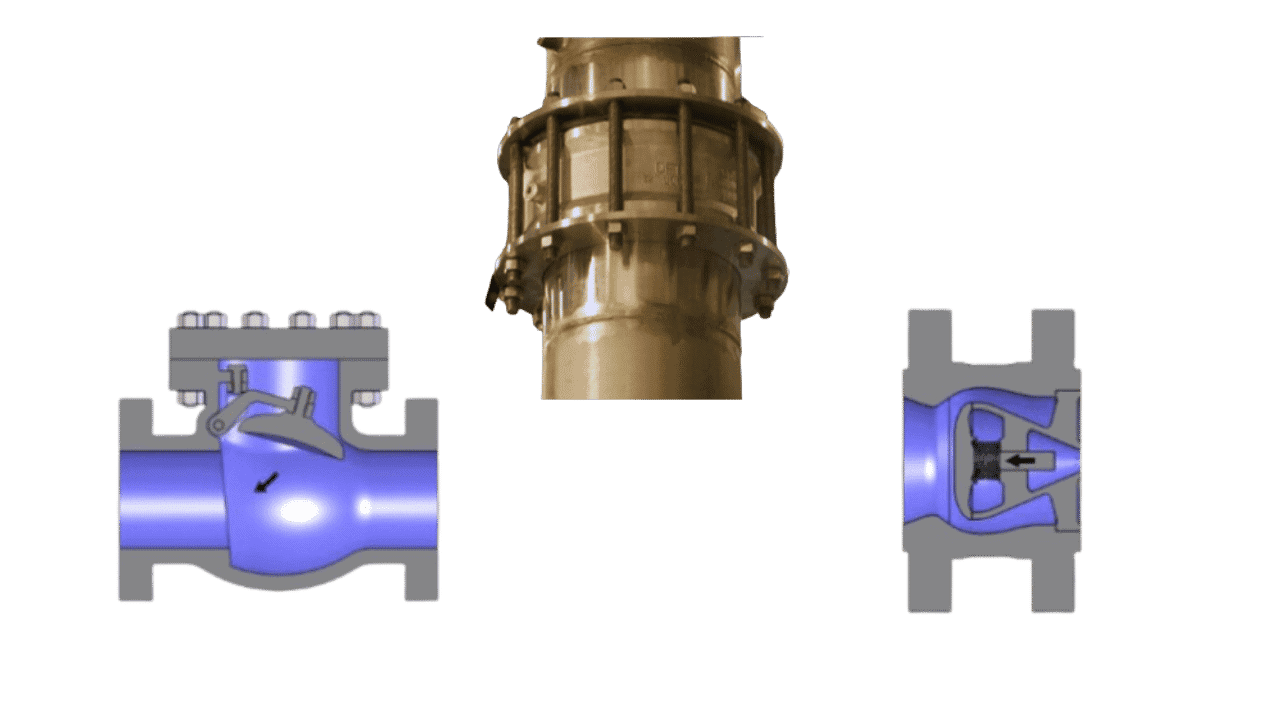

Check valves play a pivotal role in industrial piping systems by providing critical backflow prevention, ensuring that processes continue to operate efficiently and safely. However, when carrying out engineering activities, a process engineer should recognize his needs and the main issues the system might face. Based on these issues, the process engineer may add additional […]

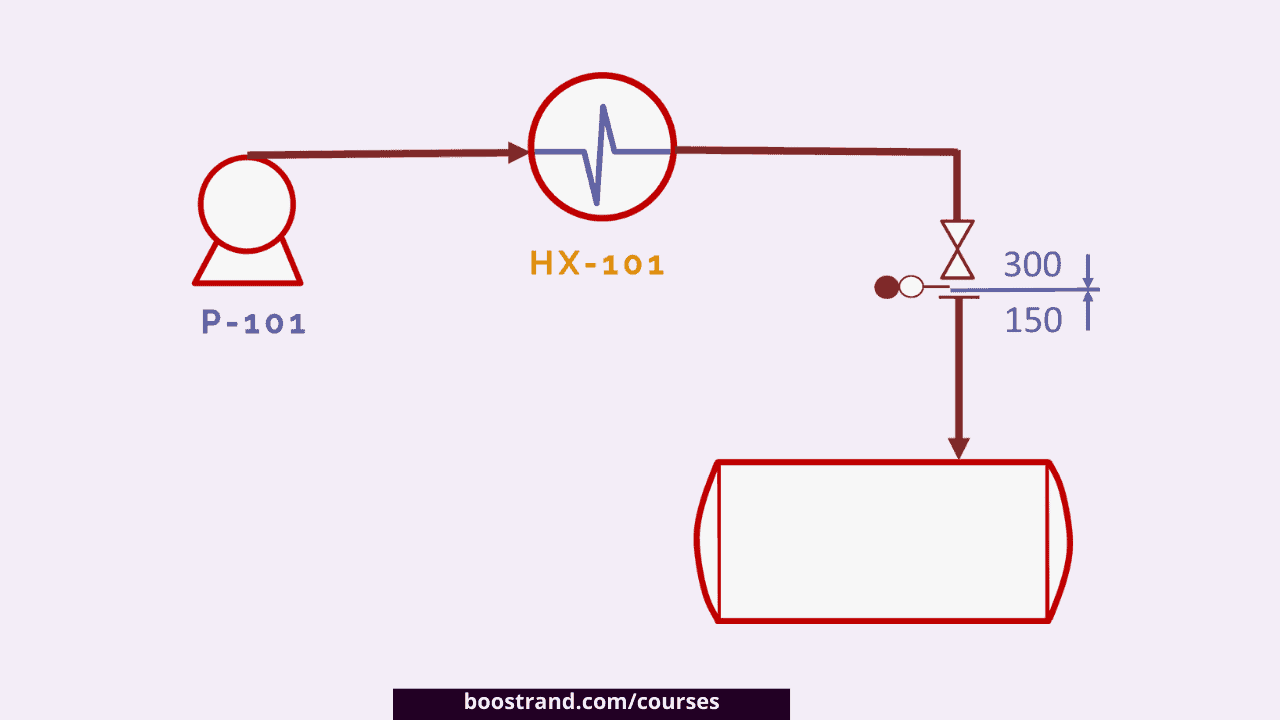

Background In the design of a new petrochemical plant, a centrifugal pump (P-101) was added to circulate the feedstock through a series of downstream equipment, including a heat exchanger (HX-101), which was critical to the operation. The pump was selected based on the process requirements, its main specifications were made based on basic hydraulic calculations. […]

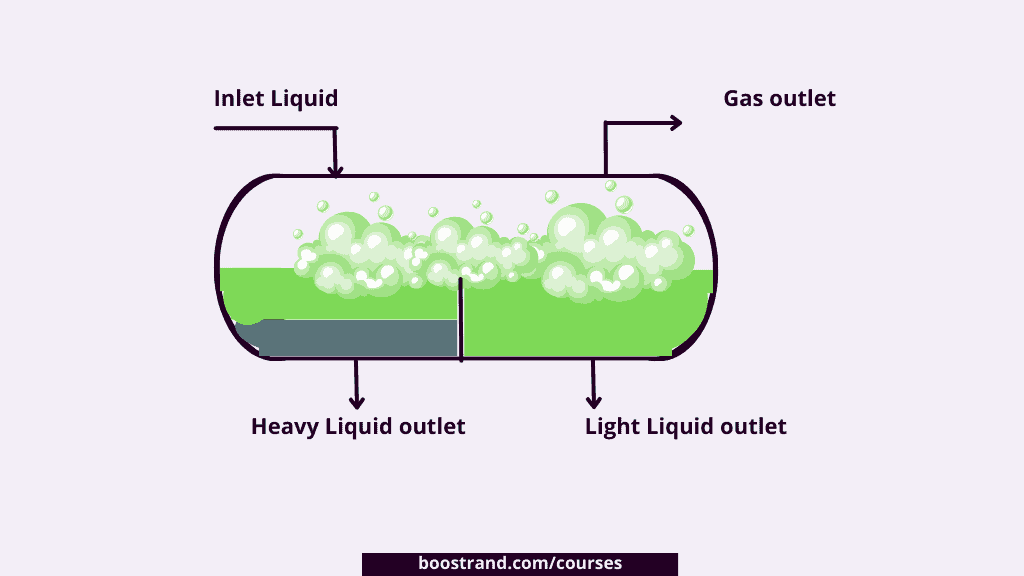

In a 3-phase separator at a crude oil production facility, operators started to notice that there were frequent overshoots in the level reading. In addition, as the gas is sent to a compression system, it was noticed that the downstream compressor suction scrubber started to receive more liquids than usual. Remember that the compressor suction […]

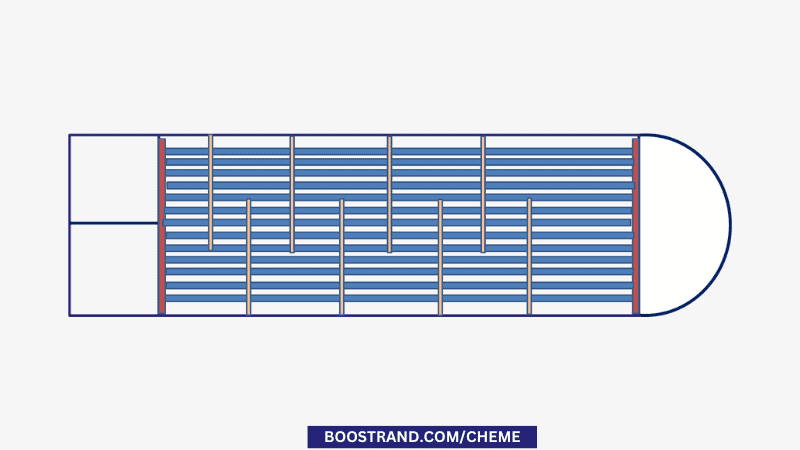

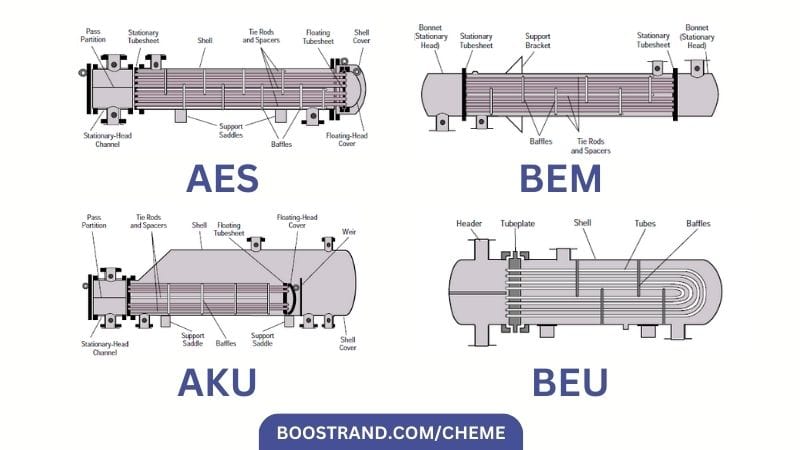

Shell and tube heat exchangers are the backbone of many industries, offering a versatile solution for heat transfer processes. If you went through any refinery or gas plant or chemical or petrochemical plants, you must have seen plenty of shell and tube exchangers. In this article, we shall go through the core aspects of optimizing […]

Introduction In any oil facility, gas plant, or chemical or petrochemical plant, pressure safety valves (PSVs) play a crucial role in preventing damage and ensuring the safe operation of plant components such as equipment or piping,..etc. While their function might seem simple, their selection, sizing, and operation involve a myriad of factors that require careful […]

Introduction Choosing the right heat exchanger for your specific service is a critical decision that can significantly impact the efficiency and cost-effectiveness, operation, and maintenance of your shell and tube heat exchanger. That’s why selecting the optimum Exchanger TEMA (Tubular Exchanger Manufacturers Association) type is crucial to ensure optimal performance and easy maintenance. In this […]

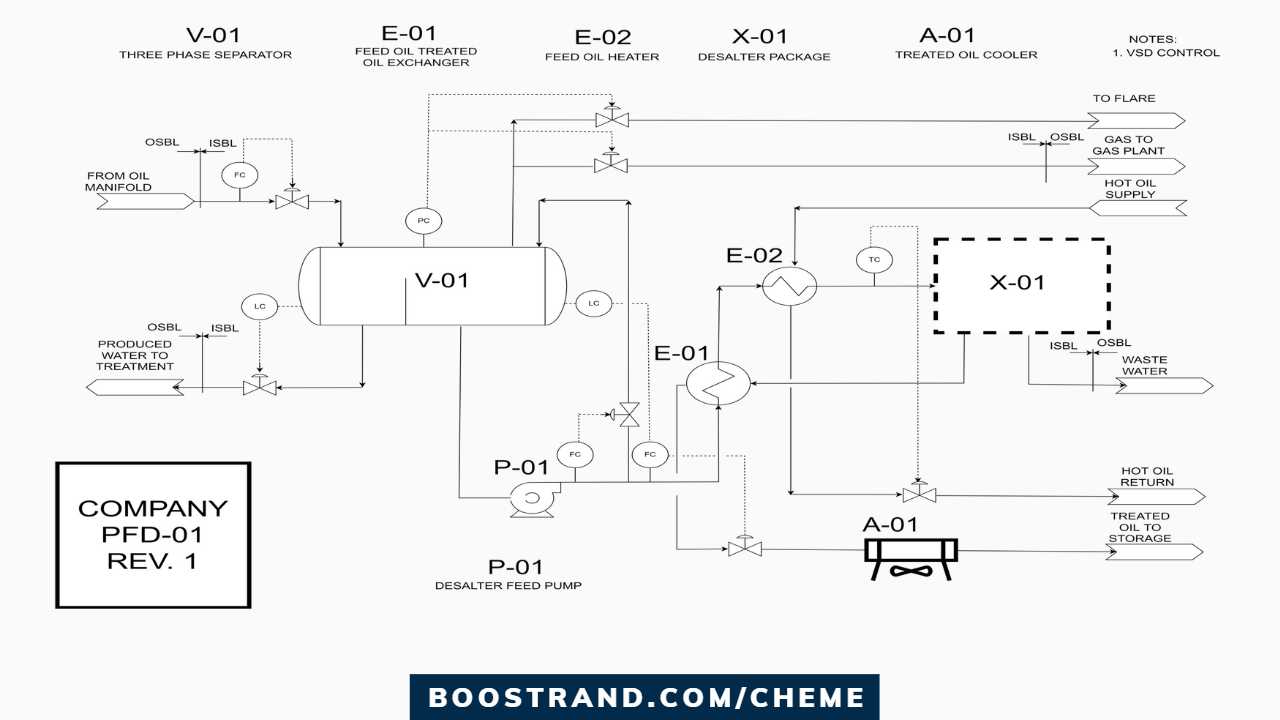

So we started our project, we carried out our plant simulation activities, and we modeled different cases using simulation software. Now, it’s time to wrap up all that we have modeled. This is an essential step in order to move forward in the project. Here comes the role of a Process Flow Diagram (PFD). A […]

Process engineering plays a pivotal role in industries such as chemical, oil and gas, petrochemical, and pharmaceuticals. It encompasses designing and optimizing processes that convert raw materials into valuable products. As the backbone of a project, process engineers collaborate closely with various disciplines, including piping, instrumentation, and mechanical engineering. Their primary objective is to ensure […]

Process design plays a crucial role in the success of any plant operation. It’s a long journey starting from process modeling and passing through sizing and design activities, then ensuring that process components are procured as requested up to starting up the plant at site. This involves a series of decisions and calculations, including equipment […]

A process engineer has a great role in any oil and gas, chemical, or petrochemical project. This is because based on the process design he performs, the cost and schedule of the project, operability and safety of the plant shall be determined. In a previous article, we have talked about the process design documents and […]

Process design is the cornerstone of any successful project. That’s because a process engineer plays a crucial role in creating efficient, safe, and sustainable processes. Through a deep understanding of chemical engineering principles, a process engineer can deliver an optimized and sustainable process design. This can be seen from the start of the project when […]

- 1

- 2